Industry information

Company News

- Carved aluminum veneer, the delicate beauty of modern architecture

- Aluminum veneer curtain wall: a shining pearl of modern architecture

- Crafted with ingenuity, carved aluminum veneer showcases the magnificent transformation of modern architecture

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Aluminum veneer, the new darling of architectural aesthetics!

Industry dynamics

- New proposition for aluminum veneer: Punching trend is coming!

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Aluminum veneer has low cost

- Aluminum veneer customization, creating a new trend of personalized space!

- What is the explosion resistance of curtain wall aluminum veneer?

Frequently asked questions

- What are the product characteristics of aluminum veneer?

- What is the future market development trend of aluminum veneer?

- What is the processing and manufacturing process of aluminum veneer?

- What factors affect the production and sales of aluminum veneer?

- How to improve the product quality and performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the anti-corrosion performance of punched aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: March 14, 2025 18:18:59

- Click:0

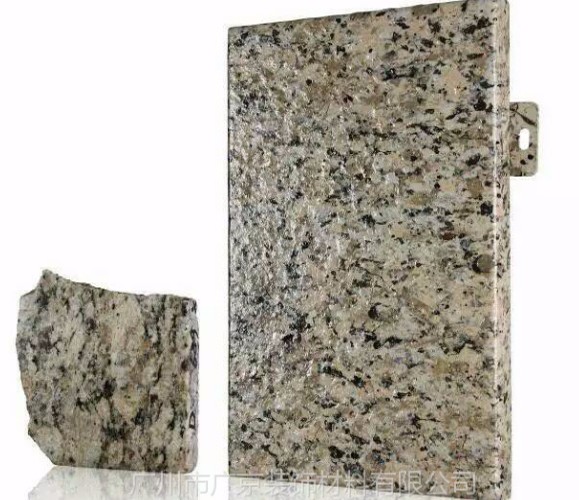

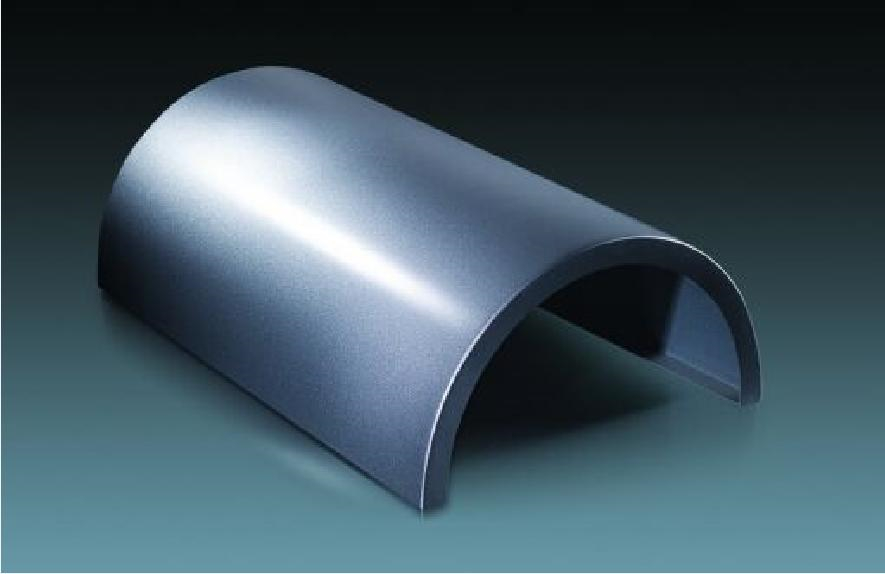

Punched aluminum veneer is a material widely used in building decoration, advertising billboards, curtain walls, and other fields. It has the advantages of light weight, high strength, corrosion resistance, and fire resistance. Corrosion resistance is one of the important characteristics of punched aluminum veneer. The following will provide a detailed introduction from the following aspects.

1. The role of the oxide layer

The surface of punched aluminum veneer is usually treated with anodizing, which can form a dense oxide film that effectively isolates air and moisture, preventing corrosion and oxidation of the aluminum material. The oxide film can also increase the hardness and wear resistance of punched aluminum veneer surface, thereby improving its service life and decorative effect.

1. The function of the coating

In addition to using anodizing treatment, punched aluminum veneer can also be coated with other methods to improve its anti-corrosion performance. For example, fluorocarbon spraying or polyester spraying can be used to coat the surface of punched aluminum veneer to enhance its weather resistance and corrosion resistance. These coatings not only protect the surface of punched aluminum veneer from oxidation or corrosion, but also enhance its color and glossiness, thereby enhancing its decorative effect.

1. The role of alloy composition

The alloy composition of punched aluminum veneer is also an important factor affecting its anti-corrosion performance. Generally speaking, the alloy composition of aluminum alloys contains a large amount of elements such as manganese and magnesium, which can effectively improve the oxidation resistance and corrosion resistance of aluminum alloys. Some special alloys such as stainless steel, titanium alloy, etc. can also be used for the production of punched aluminum veneer to meet different usage needs.

1. The impact of environmental factors

In addition to the material itself, environmental factors can also affect the anti-corrosion performance of punched aluminum veneer. For example, environments with high humidity can easily lead to rusting and corrosion on the surface of punched aluminum veneer; An environment with direct sunlight can easily cause color fading and a decrease in glossiness on the surface of punched aluminum veneer. When using punched aluminum veneer, attention should be paid to its installation environment and maintenance methods to ensure that it maintains good anti-corrosion performance in the long term.

The anti-corrosion performance of punched aluminum veneer is mainly determined by multiple factors such as the material itself, the effect of coatings, the effect of alloy composition, and the influence of environmental factors. When selecting and using punched aluminum veneer, it is necessary to choose and maintain it according to actual needs to ensure that it has good anti-corrosion performance and a long service life.

Customer service QQ

Customer service QQ