Frequently asked questions

Company News

- The fashionable transformation of aluminum veneer: not just building materials, it's art!

- The importance of aluminum veneer in environmentally friendly decoration

- The application of aluminum veneer in the field of photovoltaics

- Punched aluminum veneer: a fashionable choice in modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

Industry dynamics

- Fluorocarbon aluminum veneer: the "light luxury" choice for modern architecture

- Curtain wall aluminum veneer: a perfect fusion of architectural aesthetics and practicality

- Combining art and practicality, engineering carving aluminum veneer is applied in a new field of interior decoration

- Introduction to the characteristics and advantages of 3mm stone patterned aluminum veneer

- Before purchasing fluorocarbon aluminum veneer, it is important to understand the quality inspection reports of the relevant products

Frequently asked questions

- What factors affect the production and sales of aluminum veneer?

- What are the product characteristics of aluminum veneer?

- What is the sales market for aluminum veneer?

- What conditions are required for the production of aluminum veneer?

- What is the environmental performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to improve the product quality and performance of aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: February 24, 2025 16:14:05

- Click:0

1、 Material selection

Aluminum veneer is a new type of building material with advantages such as light weight, corrosion resistance, high strength, and easy processing. However, selecting materials correctly is crucial for improving product quality and performance.

Firstly, high-quality aluminum materials should be chosen. High quality aluminum materials have higher purity and fewer impurities, which can ensure that aluminum veneers are not easily bent, deformed, or oxidized during the manufacturing process.

Secondly, one should choose the thickness that suits their needs. Thin aluminum veneers may pose risks of bending and deformation, increasing the difficulty of production while also affecting the product's lifespan. On the contrary, too thick aluminum veneer will increase production costs and be difficult to process.

Finally, special attention should be paid to the selection of coatings. Coatings not only affect the surface color and appearance of aluminum veneers, but also their durability. The use of high-quality coatings can greatly improve the oxidation and corrosion resistance of aluminum veneer.

2、 Process technology

Reasonable production process technology can ensure the production efficiency and quality of aluminum veneer. Here are several important technical points:

1. Cleaning treatment: Before coating, aluminum veneer must be cleaned. This is to remove surface grease and dust, so that the coating can firmly adhere to the surface of the aluminum veneer.

2. Painting process: Painting is a crucial manufacturing step. Adopting appropriate coating techniques can ensure the quality and uniformity of the coating, and avoid problems such as bubbles and sagging.

3. Heat treatment: For finished aluminum veneer, it must undergo heat treatment to achieve the expected strength and stability. Heat treatment includes three steps: annealing, solid solution, and aging.

3、 Design optimization

Design optimization is one of the key factors in improving the quality and performance of aluminum veneer products. Here are several aspects that can be optimized for design:

1. Plate thickness: Reasonable plate thickness design can improve the strength and stability of aluminum veneer.

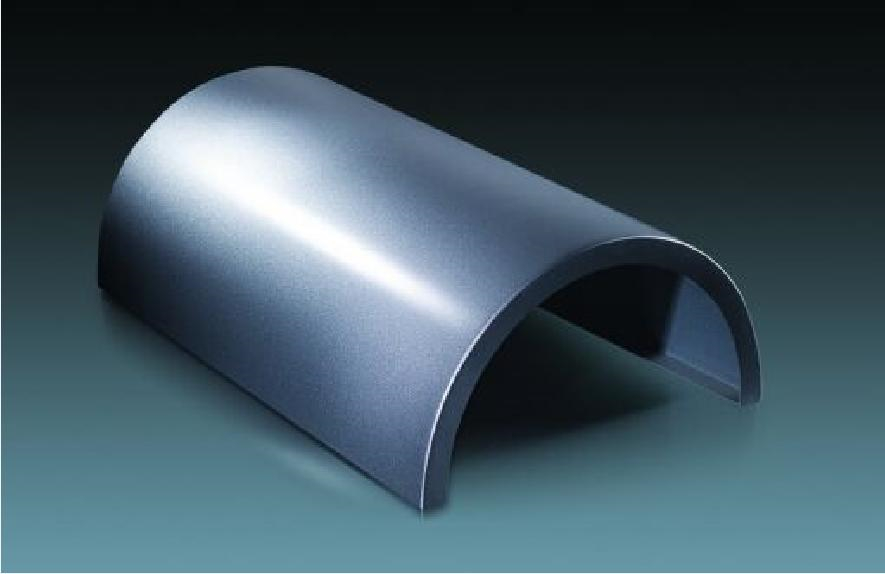

2. Profile: Proper profile design can increase the wind resistance of aluminum veneer, thereby improving the service life of the product.

3. Structure: Reasonable structural design can improve the installation and use effect of aluminum veneer, while also reducing material waste.

4、 Quality monitoring

Quality monitoring is an important means to ensure that the quality and performance of aluminum veneer products meet the requirements. Here are several commonly used quality monitoring methods:

1. Non destructive testing: Through non-destructive testing techniques such as X-rays and infrared light, some production defects that cannot be recognized by the human eye can be eliminated.

2. Sampling inspection: Sampling inspection of aluminum veneer from different batches can timely detect production problems and make adjustments.

3. Comprehensive inspection: Conduct a comprehensive inspection of the product before leaving the factory, including appearance inspection, size inspection, and other aspects, to ensure that the product meets customer requirements.

5、 Summary

Improving the product quality and performance of aluminum veneer requires efforts from multiple aspects. We need to strive for excellence in material selection, process technology, design optimization, and quality monitoring. Only in this way can we produce high-quality and highly stable aluminum veneer products, meet customer needs, and win market competition.

- Previous Page: None

- Next page:What conditions are required for the production of aluminum veneer?

Customer service QQ

Customer service QQ