Industry information

Company News

- Customized aluminum veneer, creating a new choice for personalized space!

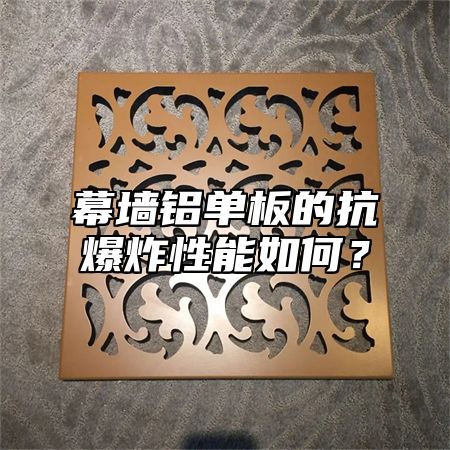

- The charm of carved aluminum veneer: delicate notes of modern architecture

- Aluminum veneer customization, creating personalized spatial aesthetics

- The importance of aluminum veneer in environmentally friendly decoration

- Punched aluminum veneer: a fashionable choice for modern architecture

Industry dynamics

- Punched aluminum veneer: the new favorite of fashionable architecture, revealing its charm!

- Aluminum veneer customization, creating a new trend of personalized space

- The advantages and applications of aluminum veneer material

- Punched aluminum veneer, the new favorite of modern architectural aesthetics

- Comparison of advantages and disadvantages of brushed aluminum veneer

Frequently asked questions

- What is the future market development trend of aluminum veneer?

- What is the sales market for aluminum veneer?

- What safety issues should be paid attention to in the production and manufacturing of aluminum veneer?

- What are the product characteristics of aluminum veneer?

- What are the applications of aluminum veneer in architectural decoration?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the explosion resistance of curtain wall aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-09 08:06:06

- Click:0

In modern architecture, curtain wall aluminum veneer, as a common exterior wall decoration material, needs to have certain anti explosion performance to ensure the safety of the building. The anti explosion performance of curtain wall aluminum veneer mainly depends on factors such as its material composition, surface treatment method, and structural design. This article will provide a detailed introduction to the explosion resistance performance of curtain wall aluminum veneer, in order to help everyone better understand and choose this material.

The main components of curtain wall aluminum veneer include aluminum alloy sheet, glass, sealant, etc. Aluminum alloy sheet is its main source of blast resistance. Aluminum alloy sheet has high strength and hardness, which can effectively resist external impact and pressure. Aluminum alloy sheets also have good heat resistance and corrosion resistance, which can extend their service life to a certain extent.

The design of curtain wall aluminum veneer is also an important factor in its blast resistance performance. Generally speaking, the design of curtain wall aluminum veneer will consider reducing the impact of structure on its blast resistance performance. For example, some designs may adopt a double-layer or multi-layer structure to increase the number and thickness of insulation and sound insulation layers, thereby reducing the impact of the structure on surface blast resistance performance. Special explosion-proof film or explosion-proof coating materials will also be used to improve the surface's explosion-proof performance. Some advanced curtain wall aluminum veneers are also equipped with automatic cleaning systems to maintain their good explosion-proof performance through regular cleaning and maintenance.

The use and maintenance of curtain wall aluminum veneer are also important factors affecting its blast resistance performance. For example, if damaged or deformed components are found during use, they should be replaced or repaired in a timely manner to prevent the impact of the structure on them. Regular cleaning and maintenance should also be carried out to maintain its good appearance and performance, thereby extending its service life.

The aluminum veneer of curtain wall has excellent blast resistance due to its excellent material properties, scientific design scheme, and strict use and maintenance. We also need to recognize that any additional anti explosion measures cannot achieve 100% effectiveness. When selecting and using curtain wall aluminum panels, we need to consider other factors comprehensively, such as structural stability and safety, in order to achieve better anti explosion effects.

Customer service QQ

Customer service QQ