Industry information

Company News

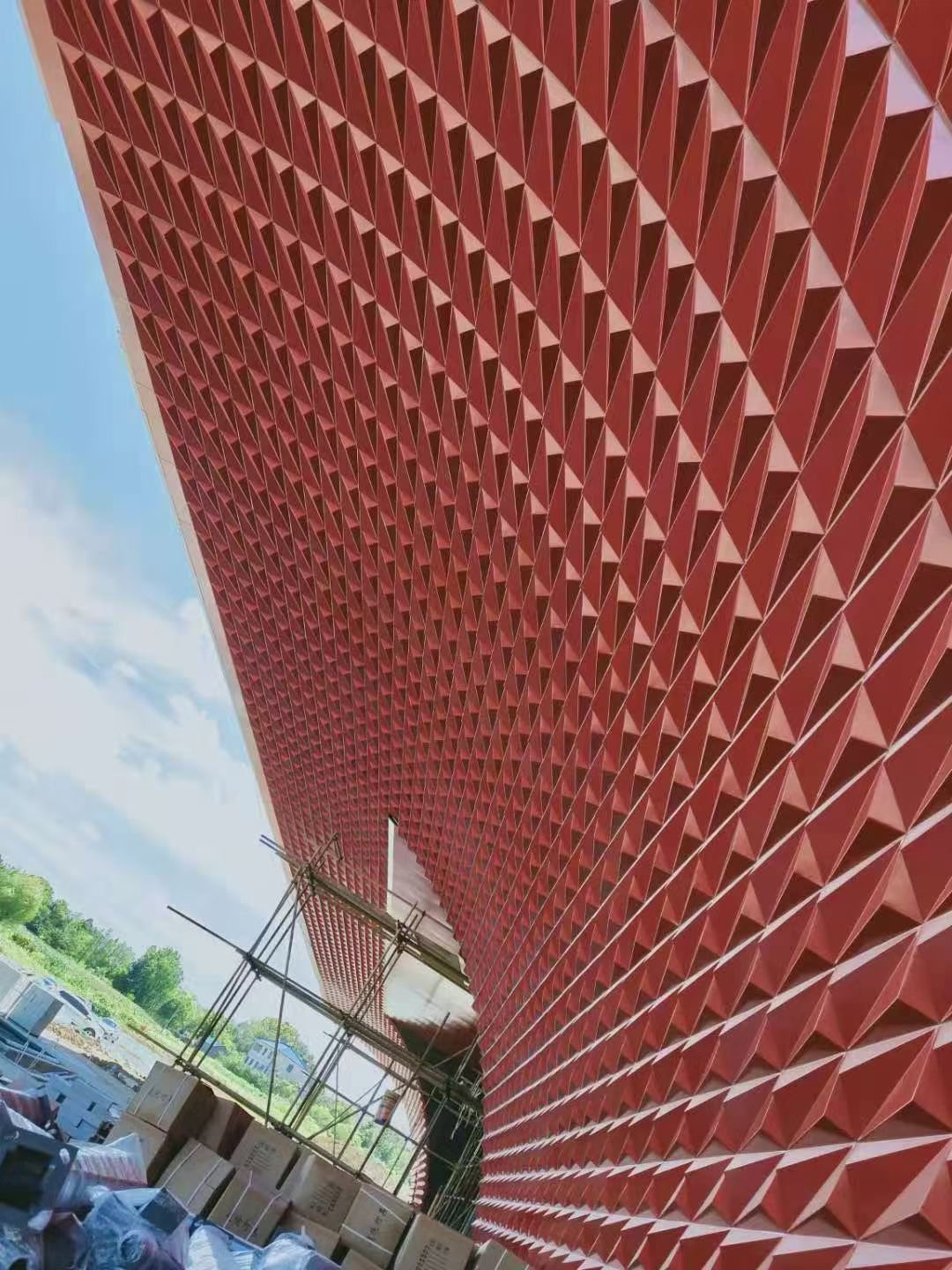

- 2. Unique creativity, carved aluminum veneer leads the trend of architectural aesthetics. 3 Carved aluminum veneer:

- Customized aluminum veneer, perfect encounter of personality and art

- Aluminum veneer: a low-key and fashionable choice in modern architecture

- The current situation and development trend of the aluminum veneer market

- New trend of aluminum plate: Punched aluminum veneer has infinite charm

Industry dynamics

- Fluorocarbon aluminum veneer: the fashionable new darling of the aluminum industry

- Punched aluminum veneer: the new darling of creative space

- Fluorocarbon aluminum veneer: the fashionable "coat" of modern architecture

- What is the energy-saving and environmental performance of aluminum veneer?

- The new favorite of exterior wall decoration, aluminum veneer, is coming!

Frequently asked questions

- What are the applications of aluminum veneer in architectural decoration?

- How to improve the product quality and performance of aluminum veneer?

- What is the processing and manufacturing process of aluminum veneer?

- What is the future market development trend of aluminum veneer?

- What factors affect the production and sales of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to establish the strength testing standards for punched aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-15 04:47:08

- Click:0

Punched aluminum veneer, as a widely used material in fields such as architectural decoration, billboards, curtain walls, etc., its strength performance is also an important aspect. The strength performance can affect the service life and safety of punched aluminum veneer. The following will introduce how to develop strength testing standards for punched aluminum veneer from the following aspects.

1. Determine the testing method

Before formulating the strength testing standards for punched aluminum veneer, it is necessary to determine the testing method. The commonly used testing methods currently include bending test, tensile test, compression test, etc. In practical operation, it is necessary to select appropriate testing methods for evaluation based on different application scenarios and requirements.

1. Determine testing standards

Before formulating the strength testing standards for punched aluminum veneer, it is necessary to determine the testing standards. The testing standards should include testing items, testing parameters, testing methods, testing equipment, and testing results. The testing standards should have operability and comparability to ensure quality consistency between punched aluminum veneers produced by different manufacturers.

1. Determine the testing indicators

Before formulating the strength testing standards for punched aluminum veneer, it is necessary to determine the testing indicators. Test indicators are important parameters used to measure the strength performance of punched aluminum veneer, usually including yield strength, tensile strength, compressive strength, etc. When developing testing indicators, it is important to ensure compliance with international standards while also considering the actual domestic situation and market demand.

How to establish strength testing standards for punched aluminum veneer?

In order to establish strength testing standards for punched aluminum veneer, the following measures can be taken:

(1) Refer to international standards and industry norms to understand relevant testing methods and indicators;

(2) Based on the actual situation and market demand, determine testing methods and indicators that are suitable for China's national conditions;

(3) Organize experts to review and confirm testing methods and indicators;

(4) Regularly revise and improve testing standards to adapt to market and technological changes.

Customer service QQ

Customer service QQ