Industry information

Company News

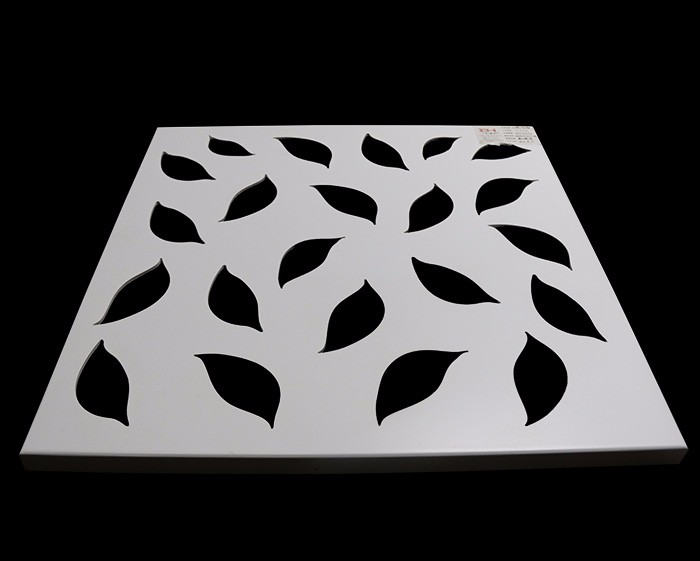

- Customized aluminum veneer, perfect encounter of personality and art

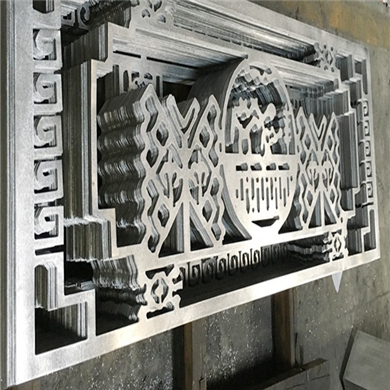

- Carved aluminum veneer: the finishing touch of modern architectural art

- The fashion journey of aluminum veneer: the perfect combination of lightness and sturdiness

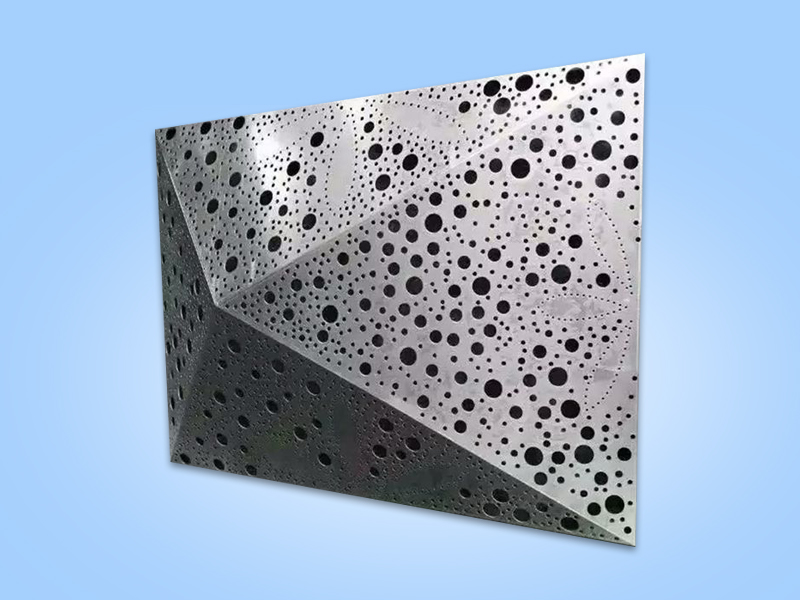

- Punched aluminum veneer, the fashionable "hole" elf in the aluminum industry

- Unveiling Punched Aluminum Veneer: Fashion Elements in Modern Architecture

Industry dynamics

- The perfect combination of personalized custom art and practicality - decorative carved aluminum veneer

- The best choice for changing the appearance of buildings with aluminum veneer

- Antique New Materials, Carved Aluminum Veneer: A Perfect Encounter between Modernity and Tradition

- Fluorocarbon aluminum veneer: the new darling of modern architecture

- Fluorocarbon aluminum veneer: low-key luxury in the construction industry

Frequently asked questions

- What are the applications of aluminum veneer in architectural decoration?

- What are the product characteristics of aluminum veneer?

- What factors affect the production and sales of aluminum veneer?

- What safety issues should be paid attention to in the production and manufacturing of aluminum veneer?

- How to improve the product quality and performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

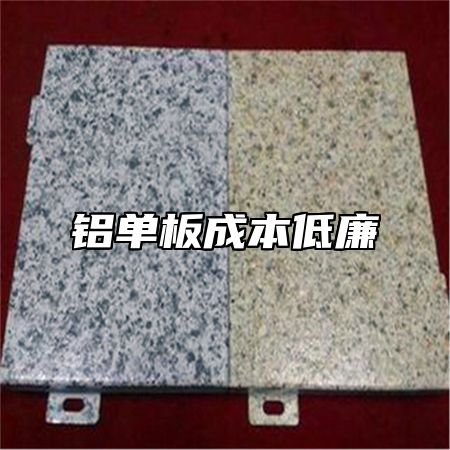

Aluminum veneer has low cost

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-02 18:18:18:49

- Click:0

Fluorocarbon aluminum veneer, as a building material, is highly favored in the market due to its low cost. Below is a detailed introduction to the cost performance of fluorocarbon aluminum veneer.

1、 The cost of the material itself is low

Fluorocarbon aluminum veneer is processed and manufactured using high-quality aluminum alloy materials, which have lower raw material costs compared to other building materials. Fluorocarbon aluminum veneer has a lower density and lighter weight, which can reduce the burden on buildings and lower construction costs. Compared with other building materials, the production cost of fluorocarbon aluminum veneer is relatively low.

2、 Simple surface treatment method

In order to improve the aesthetics and anti-corrosion performance of fluorocarbon aluminum veneer, special surface treatment is required. The commonly used methods include anodizing, spraying, electrophoretic coating, etc. These methods are relatively simple and easy to implement, without the need for complex equipment and technology, thus reducing production costs. Various colors of coatings can also be sprayed on fluorocarbon aluminum veneer to further enhance its decorative effect. This surface treatment method can not only improve the aesthetics and anti-corrosion performance of fluorocarbon aluminum veneer, but also increase its service life.

3、 Strong recyclability

Fluorocarbon aluminum veneer is a recyclable building material that can be reused multiple times. Compared to other building materials, fluorocarbon aluminum veneer has stronger recyclability and can reduce waste disposal costs. Fluorocarbon aluminum veneer can also undergo secondary processing and reuse, such as being used as a part of building decoration materials or for manufacturing other products. This can not only reduce production costs, but also minimize resource waste and environmental pollution.

4、 Strict quality inspection

In order to ensure the quality of fluorocarbon aluminum veneer, manufacturers will conduct strict quality inspection and testing on it. These tests include aspects such as material strength, hardness, corrosion resistance, as well as product appearance and dimensional accuracy. Only products that pass these tests can be recognized as qualified products and put into the market for sale. This can also provide consumers with more reliable product quality assurance. Due to strict quality inspection, rework and repair costs caused by product quality issues can be avoided, thereby further reducing production costs.

Fluorocarbon aluminum veneer, as a building material, has many advantages and characteristics. When choosing building materials, we should pay attention to the characteristics of product cost, environmental friendliness, and service life to ensure the safety, aesthetics, and economy of the building, while also considering the impact on the environment.

Customer service QQ

Customer service QQ