Industry information

Company News

- Fluorocarbon aluminum veneer: the 'hidden hero' of the construction industry

- Fluorocarbon aluminum veneer: a fashionable choice for future architecture?

- Fluorocarbon aluminum veneer: the new darling of the construction industry, how much do you know?

- Carved aluminum veneer: a perfect fusion of architectural aesthetics and craftsmanship

- Aluminum veneer, a low-key star in the construction industry

Industry dynamics

- Fluorocarbon aluminum veneer: the new darling of architectural aesthetics?

- Ancient charm and modern style, carved aluminum veneer interprets modern home aesthetics

- Aluminum veneer customization: an artistic journey to create personalized spaces

- Carved Aluminum Veneer: An Elegant Choice for Modern Architecture, One Board, One World

- Aluminum veneer: a lightweight choice, the beauty of architecture

Frequently asked questions

- What is the environmental performance of aluminum veneer?

- What are the product characteristics of aluminum veneer?

- What is the processing and manufacturing process of aluminum veneer?

- What safety issues should be paid attention to in the production and manufacturing of aluminum veneer?

- How to improve the product quality and performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to adjust the oxidation treatment process of punched aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: March 20, 2025 03:36:12

- Click:0

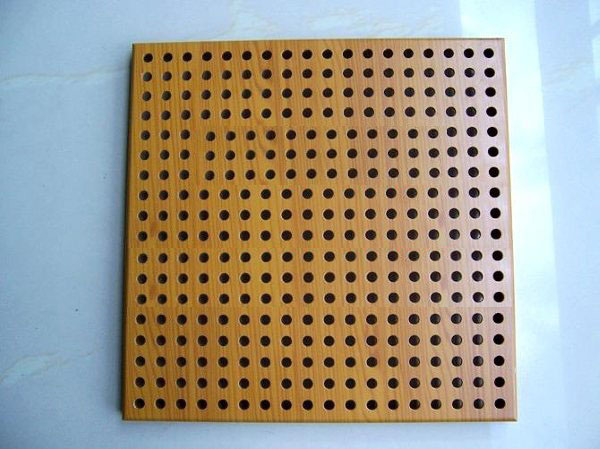

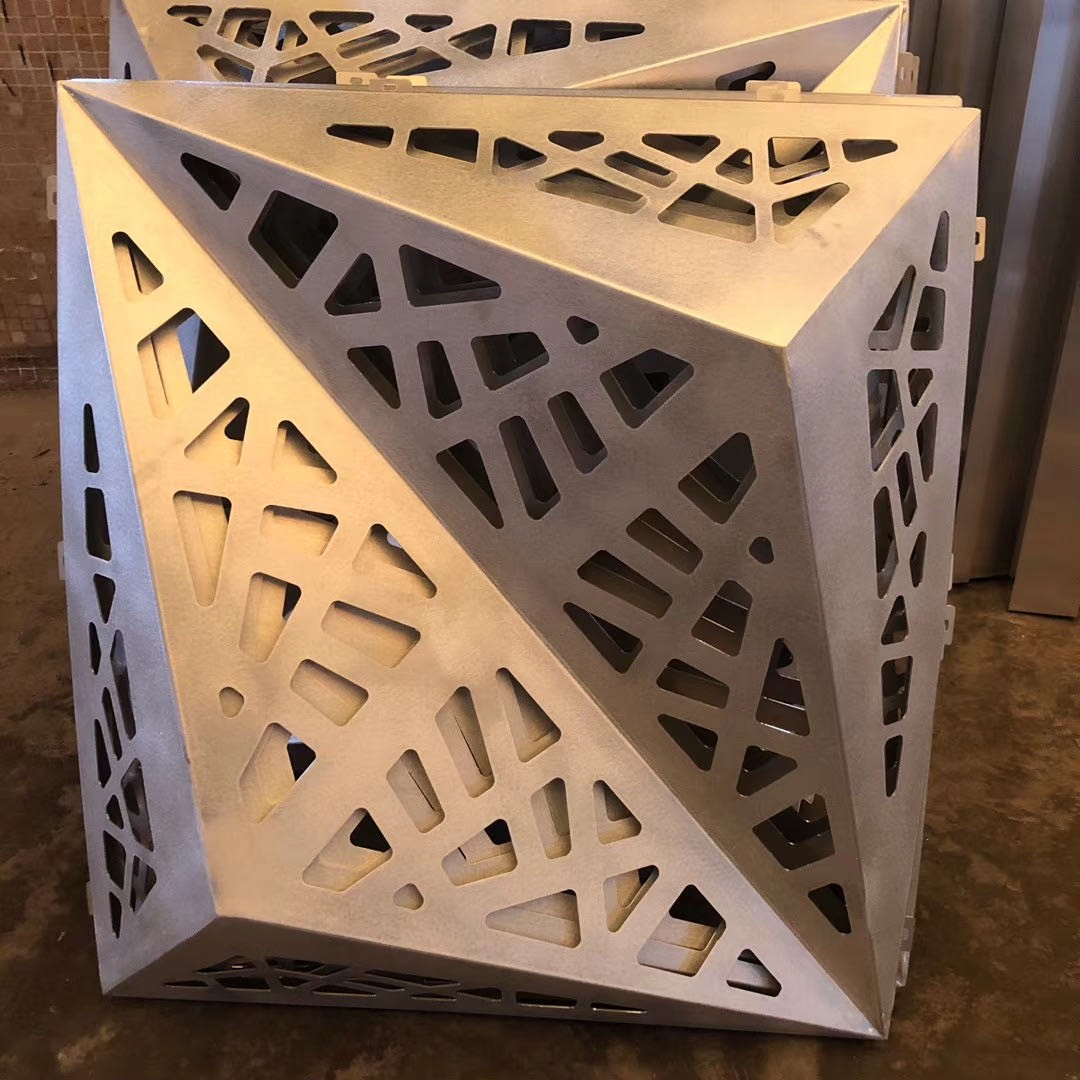

Punched aluminum veneer, as a widely used material in fields such as architectural decoration, billboards, curtain walls, etc., its oxidation treatment process is also an important aspect. Oxidation treatment can improve the corrosion resistance and aesthetics of punched aluminum veneer, but improper treatment may affect its performance and service life. The following will introduce how to adjust the oxidation treatment process of punched aluminum veneer from the following aspects.

1. Determine the processing parameters

Firstly, it is necessary to determine the oxidation treatment process parameters for punched aluminum veneer according to the actual situation. These parameters include oxidation time, temperature, current density, etc. In practical operation, it is necessary to select appropriate process parameters for adjustment based on different materials and coatings.

1. Strengthen surface treatment process

In terms of strengthening surface treatment processes, the following measures can be taken:

(1) Strengthen pre-treatment, such as cleaning, degreasing, polishing, etc., to ensure the quality of the oxide film;

(2) Control the oxidation time and temperature to avoid cracking or discoloration of the oxide film due to excessive or prolonged oxidation;

(3) Control the current density to avoid uneven oxide film caused by excessive or insufficient current.

1. Conduct testing experiments

Before conducting oxidation treatment, a series of testing experiments are required. Specifically, testing can be conducted in the following ways:

(1) Analyze the surface oxide film of punched aluminum veneer using an electrochemical tester to determine if its quality meets the requirements;

(2) Observe the surface oxide film morphology and color of punched aluminum veneer using a microscope to determine whether it is uniform and aesthetically pleasing;

(3) Set other relevant testing parameters and conditions according to the actual situation.

How to improve the oxidation treatment effect of punched aluminum veneer?

In order to improve the oxidation treatment effect of punched aluminum veneer, the following measures can be taken:

(1) Choose high-quality raw materials and coatings to ensure their quality and performance;

(2) Strengthen production process control and management to ensure the stability and consistency of process parameters;

(3) Strengthen after-sales service and recycling to maximize the service life of punched aluminum veneer.

Customer service QQ

Customer service QQ