Industry information

Company News

- Aluminum veneer customization: the art of creating personalized spaces

- Punched aluminum veneer: the fashionable choice for modern architecture?

- Curtain wall aluminum veneer: the beauty of architecture, the choice of innovation

- Fluorocarbon aluminum veneer: the "green guard" of modern architecture

- Aluminum veneer punching creates a unique charm of modern architecture

Industry dynamics

- Innovative process of arc-shaped punched aluminum veneer improves building quality

- Aluminum veneer customization: an artistic journey to create personalized spaces

- Customized personality, new trend of aluminum veneer

- Aluminum veneer manufacturer's production management system

- How to ensure the construction safety of aluminum veneer?

Frequently asked questions

- What factors affect the production and sales of aluminum veneer?

- What are the applications of aluminum veneer in architectural decoration?

- What conditions are required for the production of aluminum veneer?

- How to improve the product quality and performance of aluminum veneer?

- What are the product characteristics of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Design and Manufacturing Process of Great Wall Punched Aluminum Veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: March 2, 2025 03:29:50

- Click:0

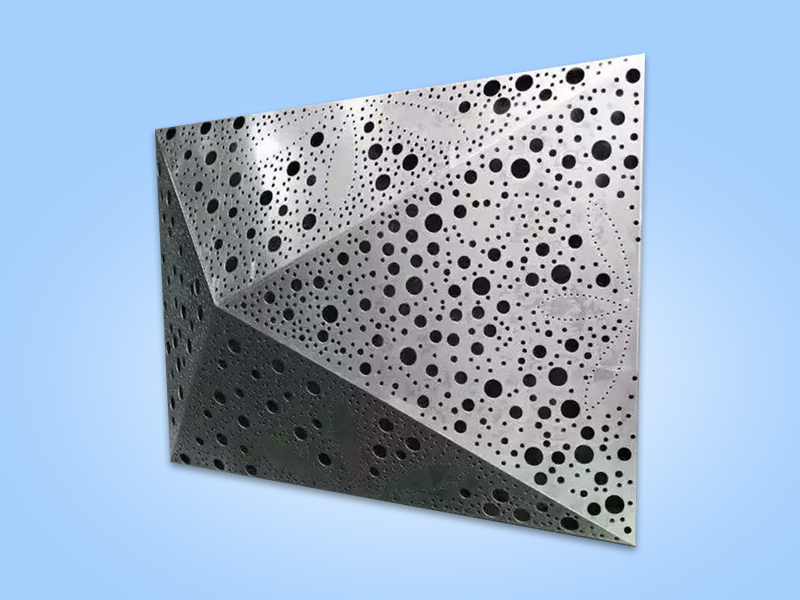

Great Wall punched aluminum veneer is a commonly used building material with advantages such as lightweight, high energy consumption, aesthetic practicality, and environmental protection and energy efficiency. Its manufacturing process is very complex and requires multiple steps to complete. This article will provide a detailed introduction to the design and manufacturing process of Great Wall punched aluminum veneer.

The design of Great Wall punched aluminum veneer needs to consider multiple factors, including shape, size, color, texture, aperture, etc. Designers need to customize according to the overall style and functional requirements of the building to achieve the best decorative effect. Designers also need to consider the size and spacing of the punched holes to ensure the strength and stability of the punched aluminum veneer.

The manufacturing process of Great Wall punched aluminum veneer includes multiple steps such as raw material preparation, sheet metal processing, CNC punching, and surface treatment. High quality aluminum alloy materials need to be selected for sheet metal processing, followed by punching treatment using CNC punching machines, and finally surface treatment such as spraying, anodizing, etc. Numerical control punching is one of the key processes that requires precise control of the punching machine's speed and force to ensure the quality and accuracy of punching.

Thirdly, the surface treatment of Great Wall punched aluminum veneer is very important. Due to its surface being frequently exposed to the natural environment, it needs to have a certain degree of durability and corrosion resistance. Usually, surface treatment processes such as spraying or anodizing are used to enhance its antioxidant, self-cleaning, and aesthetic properties.

The application range of Great Wall punched aluminum veneer is very wide. It can be used for various occasions such as exterior wall decoration, interior decoration, curtain wall decoration, etc. Due to its lightweight and high-energy characteristics and exquisite appearance design, Great Wall perforated aluminum veneer has become an indispensable part of modern architecture.

The design and manufacturing process of Great Wall punched aluminum veneer is very complex and requires multiple processes to be completed. Only through continuous innovation in design and technological improvement can a more unique and beautiful architectural appearance be achieved. The Great Wall punched aluminum veneer can also bring people a more comfortable and healthy living experience.

Customer service QQ

Customer service QQ