Industry information

Company News

- Ancient charm and new style, modern interpretation of carved aluminum veneer

- Fluorocarbon aluminum veneer: the fashionable new darling of the aluminum industry

- Fluorocarbon aluminum veneer, a new choice for architectural aesthetics!

- Aluminum veneer: the fashionable choice of modern architecture, revealing its unique charm!

- Aluminum veneer: a fashionable choice in modern architecture

Industry dynamics

- Aluminum veneer, the new darling of architectural aesthetics

- Ancient Charm and New Materials: Modern Interpretation of Carved Aluminum Veneer

- Carved aluminum veneer: artistic embellishment in modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

- Novel stone patterned aluminum veneer design

Frequently asked questions

- What is the processing and manufacturing process of aluminum veneer?

- What is the sales market for aluminum veneer?

- What are the product characteristics of aluminum veneer?

- How to improve the product quality and performance of aluminum veneer?

- What safety issues should be paid attention to in the production and manufacturing of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

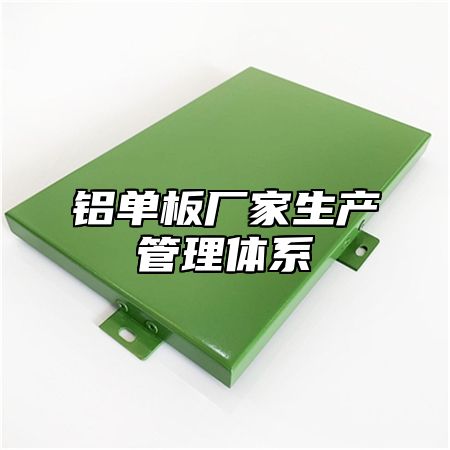

Aluminum veneer manufacturer's production management system

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-01 20:01:43

- Click:0

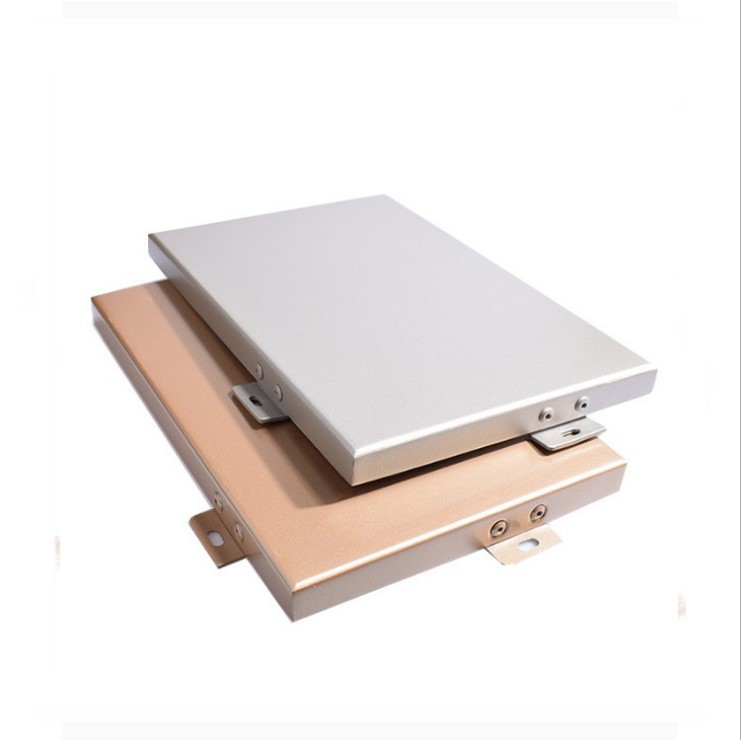

Aluminum veneer, as a new type of building material, has excellent decorative and durability properties. The production management system is an important guarantee for aluminum veneer manufacturers to improve product quality and market competitiveness. Below is a detailed introduction to the production management system of aluminum veneer manufacturers.

1、 Quality Management

1. Establish a quality management system: Aluminum veneer manufacturers should establish a sound quality management system, standardize quality management processes and standard operating procedures, and improve their quality management level.

2. Determine quality objectives: Aluminum veneer manufacturers should develop quality objectives that are in line with their own characteristics based on market demand and their actual situation.

3. Strengthen internal audits: Aluminum veneer manufacturers should strengthen internal audits, identify and correct problems, and ensure that products meet standards and customer requirements.

2、 Production Planning Management

1. Determine production plan: Aluminum veneer manufacturers should determine a reasonable production plan based on market demand and their own actual situation to ensure production progress and delivery time.

2. Strengthen material management: Aluminum veneer manufacturers should strengthen material management to ensure that the supply and use of raw materials meet standards and requirements.

3、 Production process management

1. Optimize production process: Aluminum veneer manufacturers should reduce energy consumption and exhaust emissions, and minimize their impact on the environment by optimizing production processes and technologies.

2. Strengthen process control: Aluminum veneer manufacturers should strengthen process control to ensure that products meet standards and customer requirements.

4、 Equipment management

1. Do a good job in equipment maintenance: Aluminum veneer manufacturers should do a good job in equipment maintenance to ensure the normal operation and service life of the equipment.

2. Update and upgrade equipment: Aluminum veneer manufacturers should update and upgrade equipment in a timely manner to improve production efficiency and quality.

5、 Personnel training management

1. Strengthen employee training: Aluminum veneer manufacturers should enhance employee training, improve their skills and qualities, and ensure product quality and service level.

2. Establish incentive mechanisms: Aluminum veneer manufacturers should establish incentive mechanisms to encourage employees to innovate and improve work efficiency.

6、 Security management

1. Establish a safety management system: Aluminum veneer manufacturers should establish a safety management system, standardize safety management processes and standard operating procedures, and ensure the safety and health of employees.

2. Strengthen safety training: Aluminum veneer manufacturers should enhance safety training to improve employees' safety awareness and response capabilities.

The production management system of aluminum veneer manufacturers includes multiple aspects such as quality management, production plan management, production process management, equipment management, personnel training management, and safety management. In the actual operation process, aluminum veneer manufacturers need to develop a production management system plan that meets their own characteristics based on market demand and their own actual situation, strengthen management and technological improvement, continuously improve their production efficiency and quality, and contribute to the development of the market. We also need to pay attention to issues such as environmental protection and energy conservation, continuously innovate and improve products and services, and contribute to the development of society.

Customer service QQ

Customer service QQ