Frequently asked questions

Company News

- Fluorocarbon aluminum veneer: the new darling of architectural aesthetics

- Aluminum veneer curtain wall, a new chapter in architectural aesthetics

- Carved aluminum veneer: a rising star in aluminum materials, a perfect combination of art and technology

- Aluminum veneer customization, creating an artistic journey of personalized space

- Fluorocarbon aluminum veneer: a modern interpretation of architectural aesthetics

Industry dynamics

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer curtain wall: the new darling of modern architecture, combining environmental protection and aesthetics

- Aluminum veneer: the fashionable outerwear of modern architecture

- Aluminum veneer: the fashionable new darling of modern architecture

- Aluminum veneer curtain wall, a new chapter in architectural aesthetics

Frequently asked questions

- What is the environmental performance of aluminum veneer?

- What is the sales market for aluminum veneer?

- What is the processing and manufacturing process of aluminum veneer?

- What conditions are required for the production of aluminum veneer?

- What are the applications of aluminum veneer in architectural decoration?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

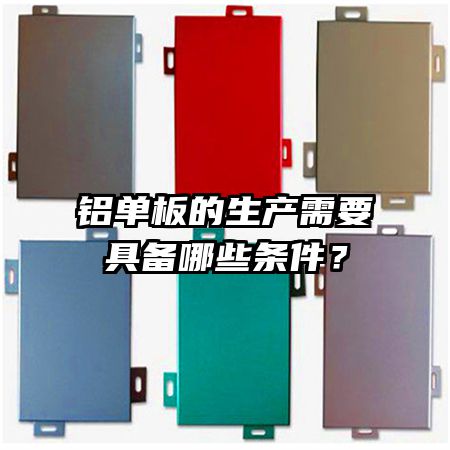

What conditions are required for the production of aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: February 23, 2025 15:46:29

- Click:0

What conditions are required for the production of aluminum veneer?

Aluminum veneer is a widely used building decoration material, widely used in high-end buildings such as walls, ceilings, and curtain walls. In the production process of aluminum veneer, certain conditions and requirements need to be met to ensure product quality and production efficiency. From the following four aspects, what conditions are required for the production of aluminum veneer.

1、 Raw material supply

As a building decoration material, the quality of aluminum veneer is directly influenced by the quality of the raw materials. Therefore, the production of aluminum veneer requires stable raw material supply channels and ensuring that the purchased raw materials comply with relevant standards and specifications. Firstly, the selection of aluminum materials should comply with national standards and possess good strength and corrosion resistance. Secondly, various auxiliary materials such as coatings, adhesives, etc. also need to ensure reliable quality to ensure the durability and appearance quality of the final product.

In addition, there needs to be a comprehensive management system for raw material supply. This includes effective monitoring and management of the procurement, warehousing, inventory, and circulation processes of raw materials to ensure their full utilization and timely replenishment. The satisfaction of these conditions is the foundation of aluminum veneer production.

2、 Advanced production equipment

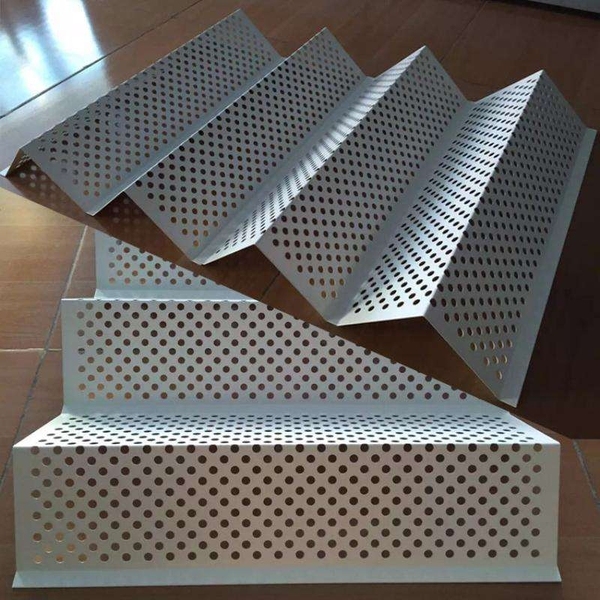

The production of aluminum veneer requires advanced production equipment to improve production efficiency and product quality. Among them, processing equipment such as shearing machines, punching machines, and bending machines can meet the needs of cutting, punching, and bending aluminum plates. In addition, cleaning and baking equipment are required to ensure the cleanliness of the aluminum plate surface and uniform coating. At the same time, testing equipment and quality inspection instruments should be equipped to strictly inspect the size, flatness, coating thickness, etc. of aluminum veneer to ensure product quality and consistency.

In addition to the high performance of the equipment itself, it also requires professional operators and technicians who can proficiently operate and maintain the equipment. Their technical level and sense of responsibility are directly related to the production efficiency and quality of the product.

3、 Scientific production technology

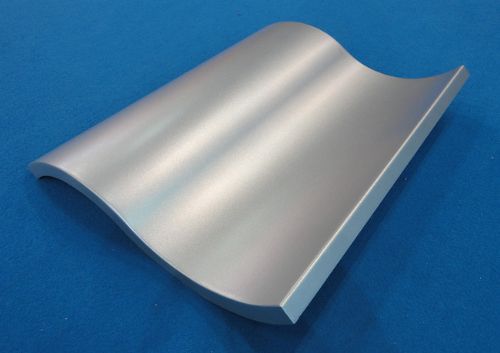

The production of aluminum veneer requires scientific production processes to ensure product quality and stability. The design of production technology needs to consider the coordination and cooperation of various links, so that the entire production process is both efficient and controllable. For example, in the cutting and bending process of aluminum plates, reasonable configuration of process parameters and operating steps can minimize waste and errors to the greatest extent possible. In the painting process, it is necessary to choose appropriate spraying methods and coatings to ensure the surface quality of aluminum veneer and the adhesion of the coating.

In addition, it is necessary to establish a sound quality control system and strictly monitor and inspect each process. Only through scientific process control and quality control can high-quality aluminum veneer products be produced.

4、 Professional team support

The production of aluminum veneer requires a professional team to provide support, including technical personnel, quality inspectors, sales personnel, etc. Technicians can provide guidance and optimization of production processes to ensure the smooth progress of the production process; Quality inspectors can conduct comprehensive quality control to ensure that products meet relevant standards. Salespeople are able to provide suitable products and solutions based on market demand.

Meanwhile, communication and collaboration among team members are also crucial, as they can jointly drive the progress of production work. With the support of a professional team, aluminum veneer production can be carried out more efficiently and orderly, meeting market demand.

Summary:

The production of aluminum veneer requires stable raw material supply, advanced production equipment, scientific production processes, and professional team support. The satisfaction of these conditions is the key to ensuring the quality and production efficiency of aluminum veneer products. Only on the basis of these conditions can high-quality aluminum veneer products be produced to meet market demand.

Customer service QQ

Customer service QQ