Industry information

Company News

- Punched aluminum veneer: the fashionable choice for modern architecture?

- Aluminum veneer curtain wall, a new chapter in architectural aesthetics

- Aluminum veneer customization, creating a new trend of personalized space!

- Fluorocarbon aluminum veneer: the new darling of architectural aesthetics?

- Ancient charm and modern style, carved aluminum veneer interprets unique aesthetics

Industry dynamics

- Material selection and performance analysis of aluminum panel curtain wall

- The charm of aluminum veneer: not just building materials, but also art!

- Carved aluminum veneer, an artistic window in modern architecture

- What is the application scope of aluminum veneer?

- Aluminum veneer: the hidden hero in modern architecture

Frequently asked questions

- What conditions are required for the production of aluminum veneer?

- How to improve the product quality and performance of aluminum veneer?

- What is the processing and manufacturing process of aluminum veneer?

- What safety issues should be paid attention to in the production and manufacturing of aluminum veneer?

- What is the future market development trend of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Customized production process of aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-13 19:21:15

- Click:0

As a new type of building decoration material, the production process of customized aluminum veneer is also crucial. Below is a detailed introduction to the production process of customized aluminum veneer.

1、 Raw material preparation

Before carrying out customized production of aluminum veneer, sufficient preparation of raw materials is required. To choose high-quality 3003 series aluminum veneer as raw material; Surface treatment should be carried out on aluminum veneer to improve its corrosion resistance and aesthetics; Thickness and color selection should be based on actual needs.

2、 Cutting and processing

The cutting and processing of aluminum veneer is a crucial step in the entire production process. Generally speaking, cutting processing involves cutting aluminum veneer into the required shape and size according to design requirements. When carrying out cutting and processing, professional cutting equipment and technology are required to ensure the accuracy of the size and shape of the aluminum veneer.

3、 Bending processing

The bending process of aluminum veneer is a very important step in the entire production process. Generally speaking, the bending process of aluminum veneer includes bending the aluminum veneer into the required angle and shape according to design requirements. When performing bending processing, professional bending equipment and technology are required to ensure that the angle and shape of the aluminum veneer meet the design requirements.

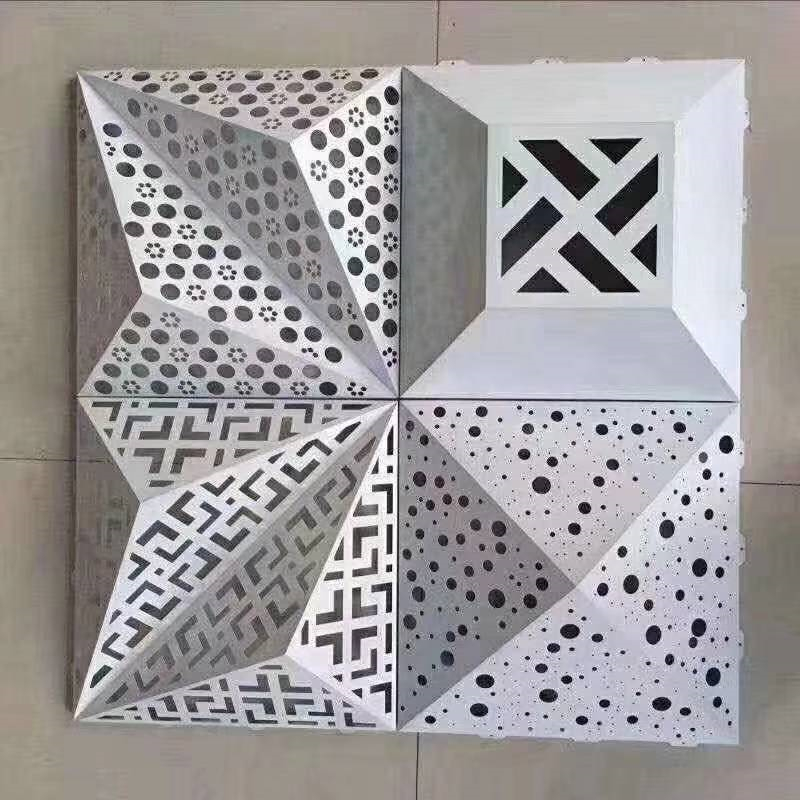

4、 Drilling processing

The punching process of aluminum veneer is a very important step in the entire production process. Generally speaking, the punching process of aluminum veneer includes punching the required holes according to the design requirements. When performing punching processing, professional punching equipment and techniques are required to ensure that the hole position and size of the aluminum veneer meet the design requirements.

5、 Welding processing

The welding process of aluminum veneer is a very important step in the entire production process. Generally speaking, the welding process of aluminum veneer includes welding the aluminum veneer according to design requirements. During welding processing, professional welding equipment and techniques are required to ensure that the welding quality of aluminum veneer meets national standards and design requirements.

6、 Surface treatment

The surface treatment of aluminum veneer is a very important step in the entire production process. Generally speaking, surface treatment of aluminum veneer includes polishing, spraying, anodizing, and other treatments. When performing surface treatment, it is necessary to use professional surface treatment equipment and techniques to ensure that the surface quality of aluminum veneer meets the design requirements.

7、 Quality inspection

The quality inspection of aluminum veneer is a very important step, which directly affects the effectiveness and safety of its use. When conducting quality inspection, it is necessary to use professional testing equipment and technology to ensure that the quality of aluminum veneer meets national standards and design requirements. Attention should also be paid to factors such as the strength, corrosion resistance, and safety performance of aluminum veneer to ensure its quality and safety.

The production process of customized aluminum veneer is very complex and critical. Only through scientific production processes and technological means can we create higher quality, more beautiful, and practical aluminum veneer products. We believe that with everyone's joint efforts, the customized aluminum veneer market will usher in a better development prospect.

Customer service QQ

Customer service QQ