Industry information

Company News

- Aluminum veneer curtain wall, the "fashionable coat" of urban architecture

- Aluminum veneer curtain wall, the fashionable coat of architecture

- The charm and creativity of punched aluminum veneer are infinite

- Property 1: Carved aluminum veneer

- Fluorocarbon aluminum veneer: low-key luxury in the construction industry

Industry dynamics

- Exquisite microporous aluminum ceiling creates high-quality indoor environment

- Aluminum veneer pricing - pricing strategy and market strategy

- Punched aluminum veneer: a unique element for creating modern architectural art

- Aluminum veneer carving, so beautiful that it makes people's hearts flutter

- Can the insulation function of aluminum veneer extend the service life of buildings?

Frequently asked questions

- What safety issues should be paid attention to in the production and manufacturing of aluminum veneer?

- What is the future market development trend of aluminum veneer?

- What is the processing and manufacturing process of aluminum veneer?

- What are the product characteristics of aluminum veneer?

- What factors affect the production and sales of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Measures to improve production efficiency of aluminum veneer production process and equipment

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: March 11, 2025 01:50:50

- Click:0

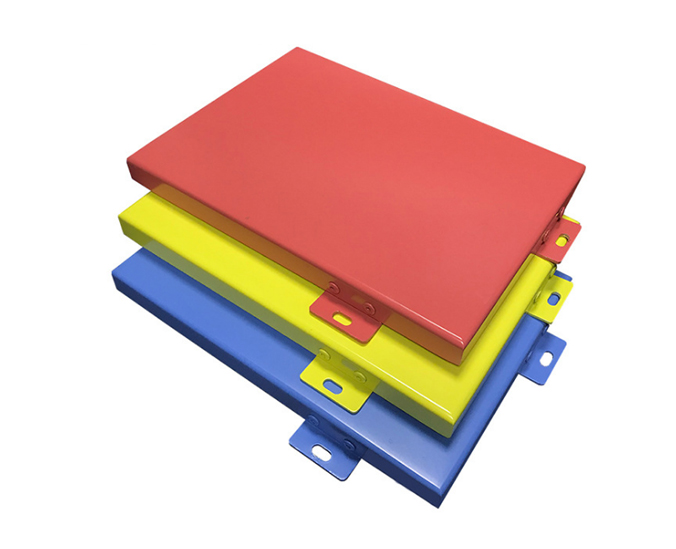

Aluminum veneer, as a new type of building material, is highly favored in the construction industry due to its lightweight, high strength, corrosion resistance, sound insulation, and other advantages. In order to improve production efficiency, aluminum veneer production enterprises need to continuously optimize their production processes and equipment. Below, we will provide a detailed introduction on how to improve production efficiency by optimizing the production process and equipment.

Aluminum veneer production enterprises can improve production efficiency by optimizing the production process. The production process includes links such as raw material procurement, processing and manufacturing, and quality inspection. Enterprises can improve production efficiency by optimizing these processes. For example, enterprises can adopt advanced raw material procurement systems to ensure the quality and supply of raw materials; Advanced processing and manufacturing equipment can be used to improve processing efficiency and accuracy; Advanced quality testing equipment can be used to improve product quality and testing efficiency.

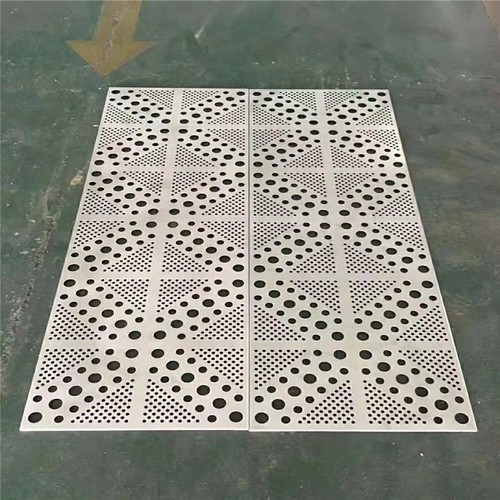

Aluminum veneer production enterprises can improve production efficiency by optimizing equipment. Equipment is an important component of the production process in aluminum veneer manufacturing enterprises, and its performance and stability directly affect production efficiency. Enterprises can optimize their equipment through the following measures:

1. Adopt advanced production equipment to improve production efficiency and accuracy;

2. Regularly maintain and upkeep the equipment to ensure its normal operation;

3. Upgrade and transform the equipment to improve its performance and reliability;

4. Intelligent transformation of equipment to achieve automated production.

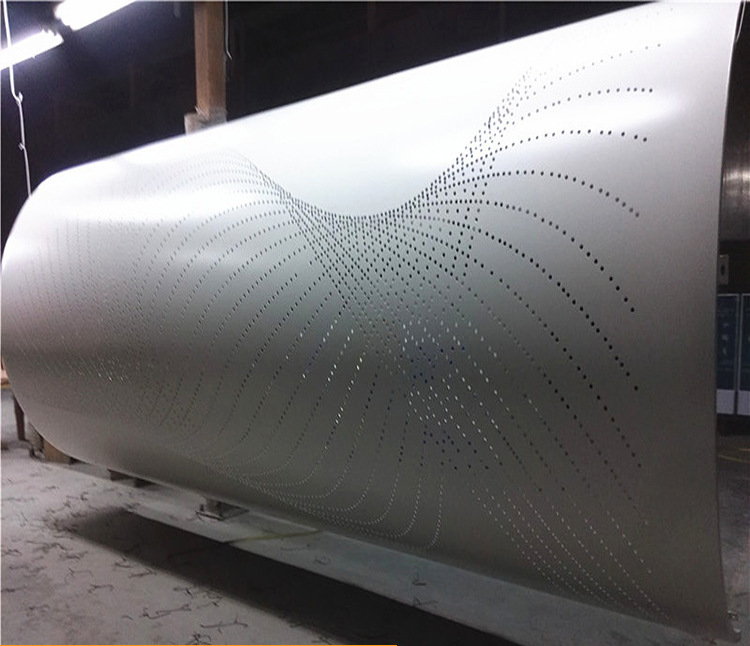

Thirdly, aluminum veneer production enterprises can improve production efficiency by optimizing management. Management is an important component of the production process in aluminum veneer manufacturing enterprises, and the quality of management directly affects production efficiency. Enterprises can optimize management through the following measures:

1. Establish a scientific management system, clarify the responsibilities and tasks of each link;

2. Strengthen personnel training and management to improve employees' skills and qualities;

3. Adopt an information management system to achieve rapid transmission and sharing of information;

4. Strengthen communication and cooperation with suppliers and customers to improve the efficiency of supply chain and customer service.

To improve the production efficiency of aluminum veneer manufacturing enterprises, it is necessary to start from multiple aspects such as optimizing the production process, equipment, and management. Only by continuously optimizing and improving each link can we improve production efficiency, reduce costs, and enhance the competitiveness of enterprises. I believe that in the future development, aluminum veneer will become one of the mainstream materials in the construction industry.

- previous page:Improvement and Innovation of Production Process for Aluminum Veneer

- Next page:Is aluminum veneer widely used?

Customer service QQ

Customer service QQ