Industry information

Company News

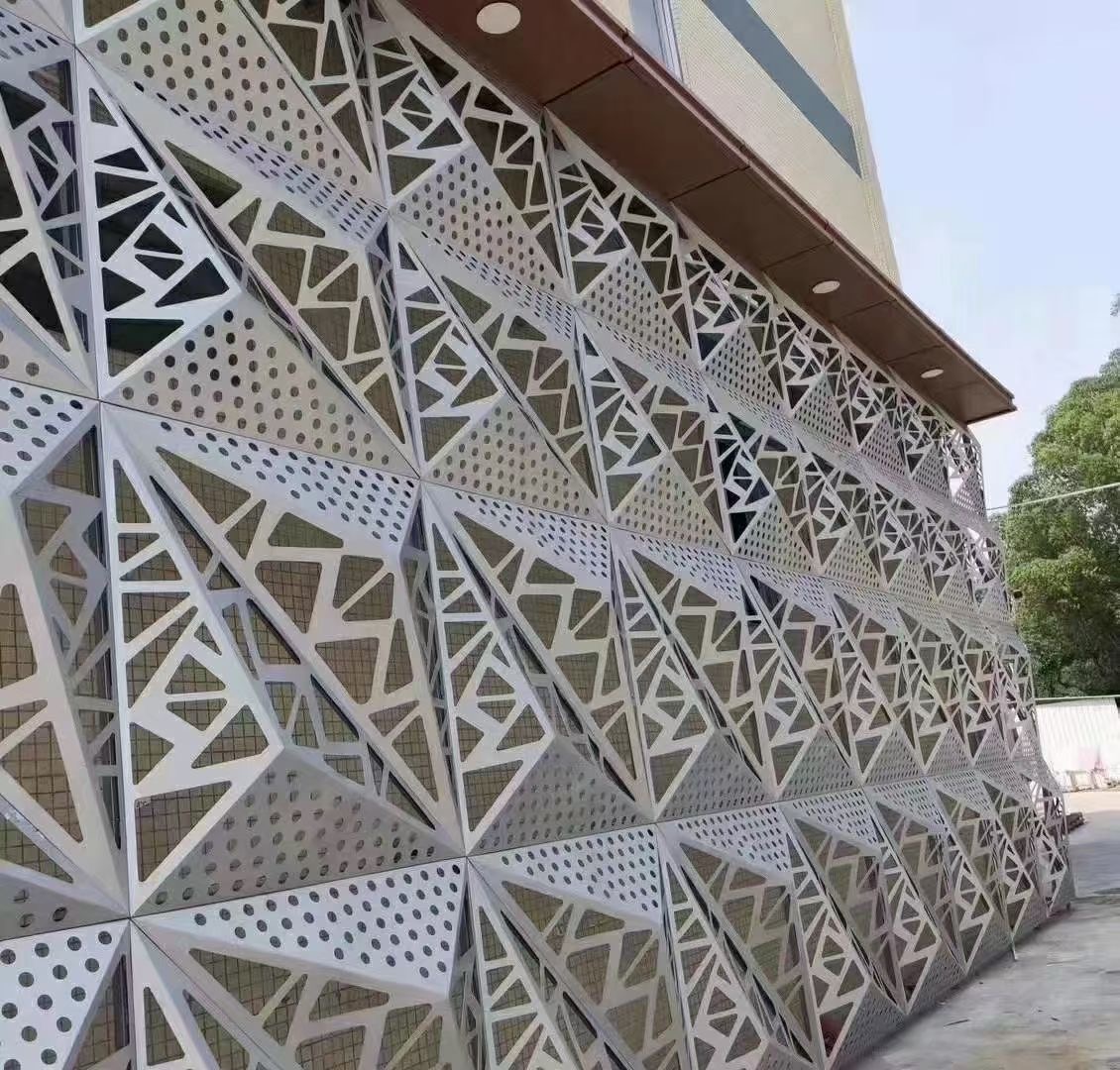

- New trend of aluminum plate: The charm of punched aluminum veneer is infinite

- Ancient charm and modern style, carved aluminum veneer interprets the beauty of modern architecture

- Fluorocarbon aluminum veneer: a new favorite in the construction industry, a lightweight and weather resistant secret weapon!

- Aluminum veneer: the 'hidden hero' of modern architecture

- Punched aluminum veneer, the new darling of modern architecture!

Industry dynamics

- Carved aluminum veneer: artistic embellishment in modern architecture

- Exploring the application prospects of hyperbolic exterior aluminum veneer in the field of architecture

- The unique charm of carved aluminum veneer, a masterpiece of art that savors life

- What is the prospect of the aluminum veneer market?

- Exploring the high-quality characteristics of punched aluminum veneer

Frequently asked questions

- What are the product characteristics of aluminum veneer?

- What is the sales market for aluminum veneer?

- What factors affect the production and sales of aluminum veneer?

- What is the processing and manufacturing process of aluminum veneer?

- What safety issues should be paid attention to in the production and manufacturing of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Improvement and Innovation of Production Process for Aluminum Veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-10 20:00:39

- Click:0

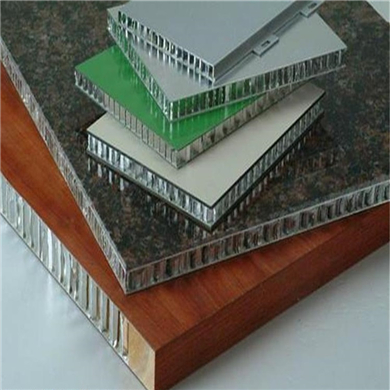

Aluminum veneer, as a new type of building material, has the advantages of lightweight, high strength, fire resistance, and recyclability, and is widely used in the construction industry. The traditional production process of aluminum veneer has some problems, such as low production efficiency and unstable product quality. In order to improve the production efficiency and product quality of aluminum veneer, it is necessary to improve and innovate the production process of aluminum veneer.

Advanced CNC equipment and automated production lines can be used to improve the production process of aluminum veneer. This approach can greatly improve production efficiency and product quality, and reduce the impact of manual operations on the product. For example, the use of CNC punching machines can achieve precise cutting and forming of aluminum veneer, improving product accuracy and consistency; The use of automated spraying machines can achieve uniform spraying on the surface of aluminum veneer, improving product quality and aesthetics.

New surface treatment techniques can be used to improve the production process of aluminum veneer. For example, the use of anodizing process can form an oxide film, improve the corrosion resistance and wear resistance of aluminum veneer, and extend its service life; The use of fluorocarbon spraying technology can make the surface of aluminum veneer have good weather resistance and UV resistance, which is suitable for outdoor building decoration. These new surface treatment technologies can improve the product quality and service life of aluminum veneer, thereby increasing its market competitiveness.

Again, green and environmentally friendly production methods can be adopted to improve the production process of aluminum veneer. For example, using harmless coatings and solvents to replace traditional harmful chemicals and reduce environmental pollution; Using renewable resources to replace the use of raw materials and reduce the consumption of natural resources. This green and environmentally friendly production method meets the requirements of modern society for sustainable development and can enhance the corporate social responsibility image and brand value.

Innovation in aluminum veneer production processes can be promoted by strengthening research and development investment and technological cooperation. For example, collaborating with universities, research institutions, etc. to conduct research and development of new materials and technologies, continuously launching innovative and differentiated products; By participating in industry exhibitions, exchange meetings, and other activities, we can understand market demand and competitors' situations, and adjust our business strategies and investment directions in a timely manner. This type of technological innovation and collaborative innovation can enhance a company's core competitiveness and market share.

The improvement and innovation of the production process of aluminum veneer, as a new type of building material, are of great significance. By adopting advanced equipment and technology, new surface treatment techniques, and green and environmentally friendly production methods, as well as strengthening research and development investment and technical cooperation, the production efficiency and product quality of aluminum veneer can be improved, the market competitiveness and brand value of enterprises can be enhanced, and the maximum return on investment can be achieved. Both investors and production enterprises need to closely monitor the new technologies and trends in the aluminum veneer industry, adjust their business strategies and investment directions in a timely manner, in order to seize market opportunities.

Customer service QQ

Customer service QQ