Industry information

Company News

- Carved aluminum veneer: a fashionable choice for modern architecture

- Punched aluminum veneer: the fashionable choice for modern architecture?

- Punched aluminum veneer: the new favorite of fashionable architecture, revealing its charm!

- Fluorocarbon aluminum veneer: a fashionable outerwear for modern architecture

- Punched aluminum veneer, creating a modern and fashionable facade trend

Industry dynamics

- Building materials display fluorocarbon aluminum veneer

- Analysis of the environmental advantages of aluminum veneer

- Carved aluminum veneer: the finishing touch of modern architecture

- Aluminum veneer curtain wall, the fashionable outerwear of modern architecture

- Unveiling "Curtain Wall Aluminum Veneer": The Secret Weapon of Modern Architecture!

Frequently asked questions

- What is the processing and manufacturing process of aluminum veneer?

- How to improve the product quality and performance of aluminum veneer?

- What conditions are required for the production of aluminum veneer?

- What is the environmental performance of aluminum veneer?

- What is the future market development trend of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Carving hollow aluminum veneer with exquisite craftsmanship and practicality

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: February 25, 2025 06:28:06

- Click:0

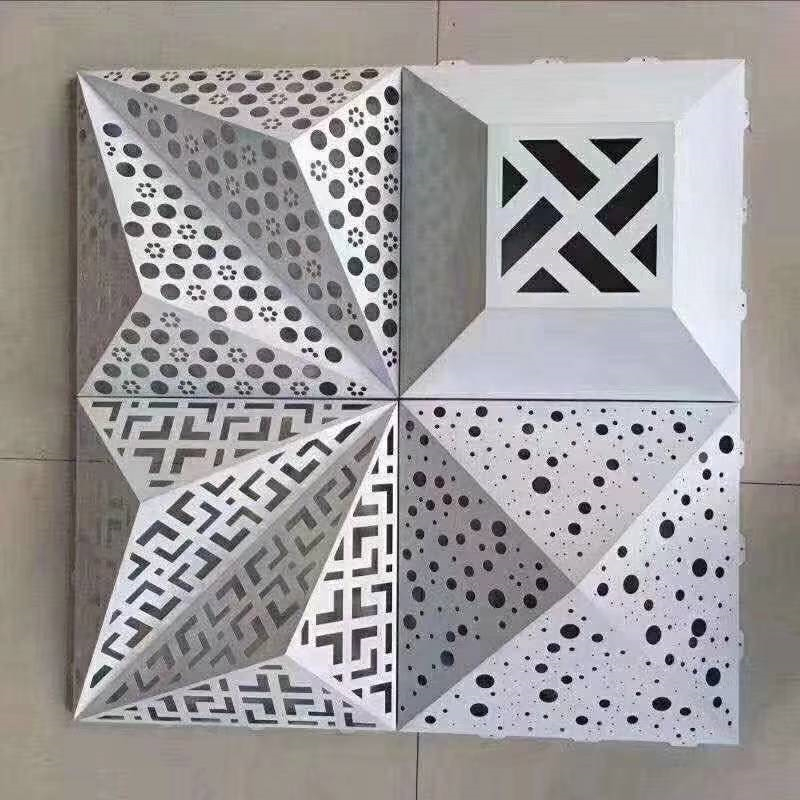

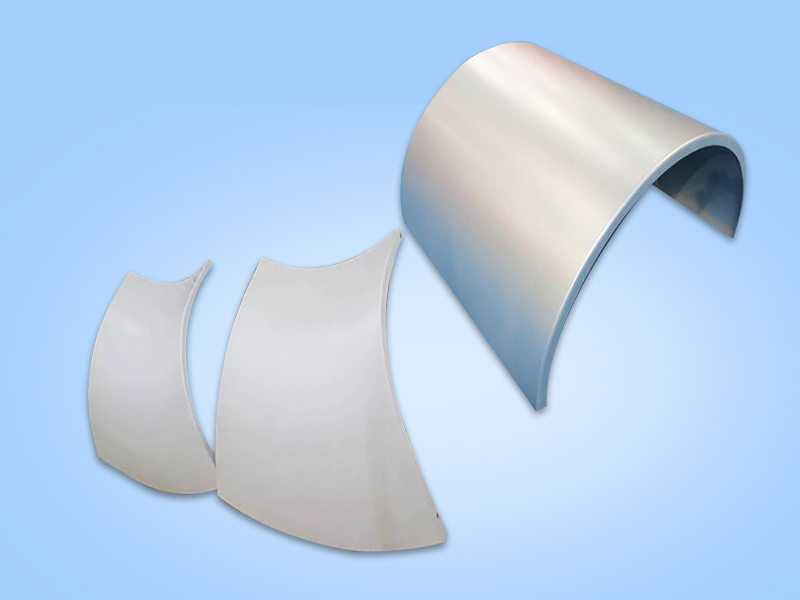

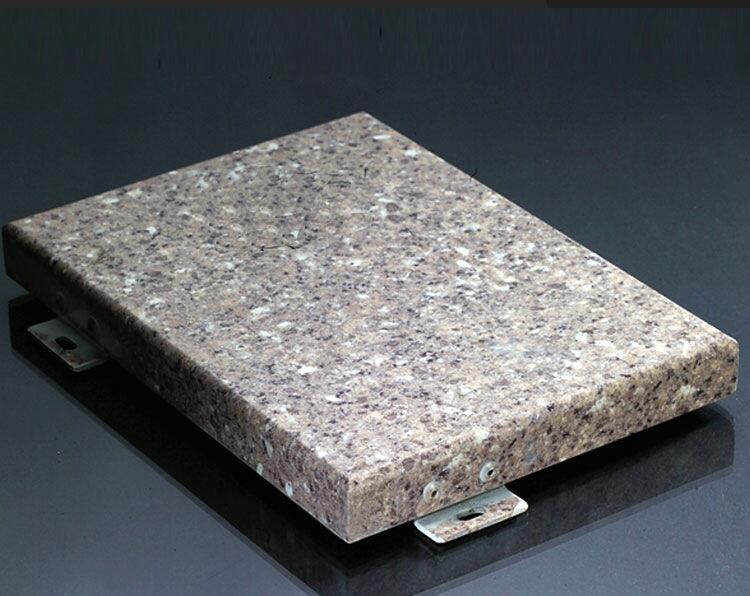

Aluminum veneer, as a new type of building material, has excellent decorative effects and durability. During the production process, carving and hollowing out are important techniques for aluminum veneer, which can bring more exquisite effects to architectural decoration. Carving hollow aluminum veneer not only has artistic value, but also practical value, making it a product that combines exquisite art and practicality.

1、 Design phase

1. Determine design plan: The designer develops a corresponding design plan based on the client's needs and the style of the building. The design plan includes requirements for patterns, colors, textures, and other aspects. Designers need to fully consider these factors to ensure that the final decorative effect meets the customer's requirements.

2. Sketching: The designer converts the design proposal into a sketch and communicates and confirms it with the client. Sketches are an important basis for making aluminum veneers and must be accurate and error free.

2、 Production stage

1. Raw material preparation: The main raw materials for aluminum veneer are aluminum plates and spray coatings. Aluminum plates need to undergo precision cutting and polishing processes to ensure a smooth and even surface. Spray coating requires selecting the appropriate color and texture according to the design plan.

2. Carving treatment: Carving treatment is one of the key technologies in the production of aluminum veneer. Through high-precision carving equipment and technology, precise carving of various materials can be achieved, resulting in more exquisite patterns and textures.

3. Hollow out treatment: Hollow out treatment is a further extension of carving treatment, which can remove some areas in the aluminum veneer through carving technology to form a unique hollow out effect. Hollow out treatment needs to consider the stability and safety of the structure, and should be operated by experienced craftsmen.

4. Spray treatment: Spray treatment is one of the key steps in the production of aluminum veneer. Spray paint needs to be evenly sprayed onto the aluminum plate to form the desired pattern and texture. During the spraying process, attention should be paid to controlling the thickness and uniformity of the coating to ensure that the final decorative effect meets the design requirements.

3、 Installation phase

1. On site measurement: Before installation, it is necessary to conduct on-site measurements of the building to determine the size and position of the aluminum veneer. The measurement results need to be compared with the design drawings to ensure installation accuracy and quality.

2. Installation and fixation: Aluminum veneer needs to be fixed to the building by welding or bolts. Pre treatment of the aluminum plate is required before fixation to ensure the firmness and safety of welding or bolts.

Carving hollow aluminum veneer not only has artistic value, but also practical value, making it a product that combines exquisite art and practicality. In the production process, it is necessary to fully consider multiple aspects such as design, production, and installation. Only by striving for excellence in each aspect can we create exquisite and unparalleled architectural decoration effects. In the future, with the continuous advancement of technology and the continuous development of society, aluminum veneer will play a more important role in creating a better and more comfortable living environment for people.

Customer service QQ

Customer service QQ