Industry information

Company News

- Curtain wall aluminum veneer, creating the beauty of modern architecture

- Aluminum veneer customization: an artistic journey to create personalized spaces

- Carved Aluminum Veneer: An Artistic Treasure in the Aluminum World

- Surface treatment and color selection of aluminum veneer

- Fluorocarbon aluminum veneer: a rising star in the aluminum industry and a star material in the construction industry

Industry dynamics

- The modern charm of aluminum veneer: not limited to architecture

- Aluminum veneer, the "fashionable coat" of modern architecture

- How to choose aluminum veneer prices that meet the budget?

- Fluorocarbon aluminum veneer: a light luxury choice for architectural art

- Aluminum veneer: the fashionable new favorite in the construction industry

Frequently asked questions

- What are the product characteristics of aluminum veneer?

- What is the future market development trend of aluminum veneer?

- How to improve the product quality and performance of aluminum veneer?

- What is the environmental performance of aluminum veneer?

- What are the applications of aluminum veneer in architectural decoration?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Fixture design and manufacturing process for 2mm aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: March 12, 2025 21:49:51

- Click:0

2mm aluminum veneer, as a commonly used tooling material, has unique advantages in tooling design and manufacturing processes. The following will provide a detailed introduction to the tooling design and manufacturing process of 2mm aluminum veneer from multiple aspects.

1、 Design requirements

1. Lightweight design

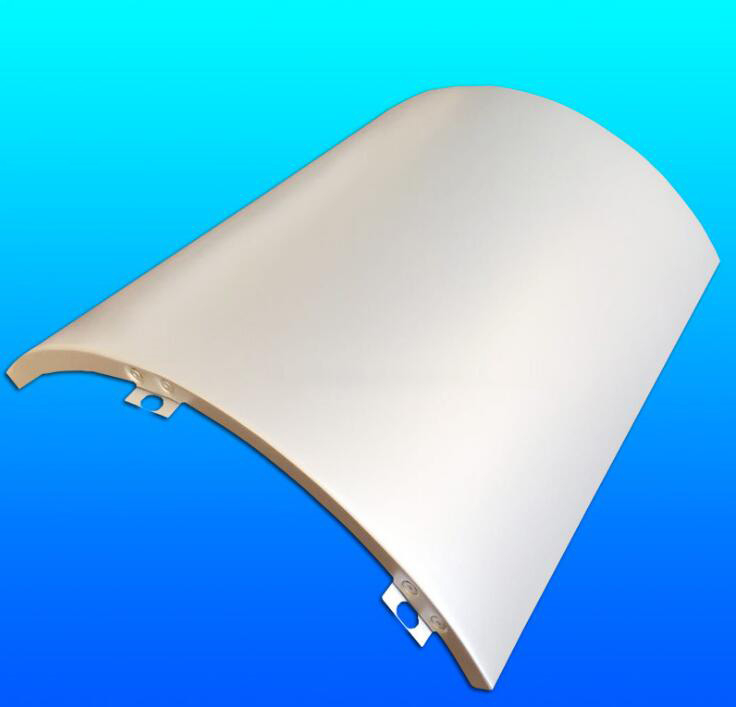

2mm aluminum veneer can be used for tooling design. Compared to traditional tooling materials such as steel and wood, 2mm aluminum veneer has a lighter weight, which can reduce the weight of buildings and lower their structural costs. Due to the excellent thermal conductivity of 2mm aluminum veneer, it can improve the insulation effect of fixtures and further save energy.

2. Good corrosion resistance

2mm aluminum veneer has good corrosion resistance, which can effectively prevent the tooling from being affected by oxidation, corrosion, etc., and extend the service life of the tooling.

3. High compressive strength

2mm aluminum veneer has high compressive strength and can effectively withstand external forces on the fixture, ensuring the safety and stability of the fixture.

2、 Production process

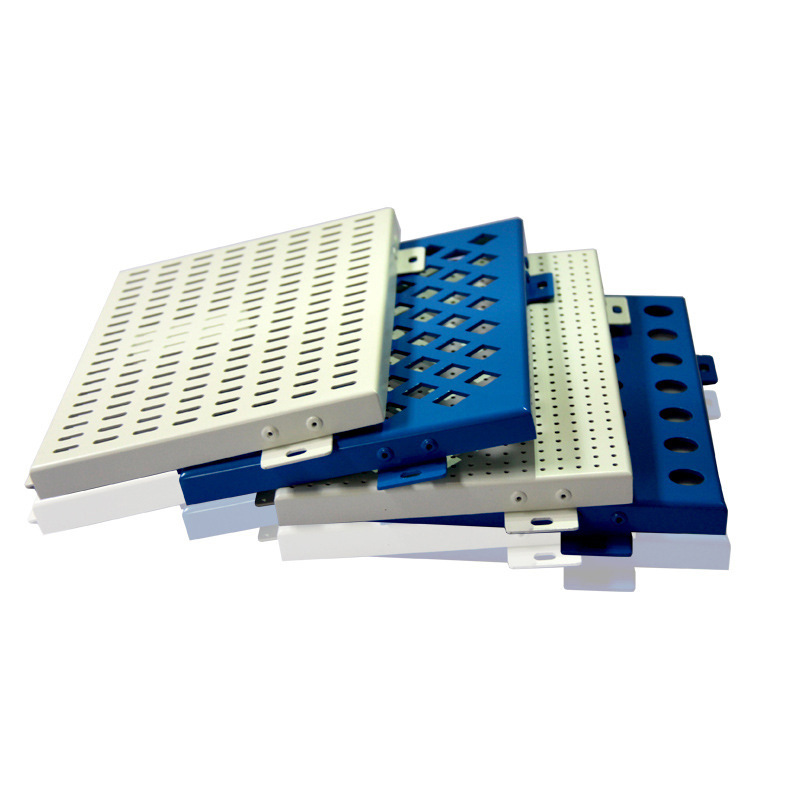

1. Cutting and processing

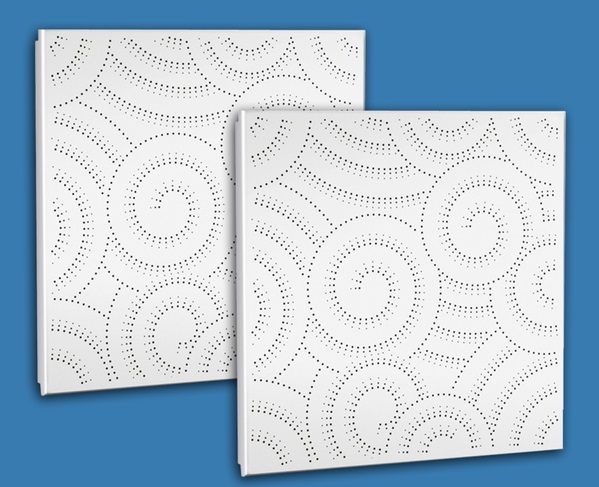

2mm aluminum veneer can be cut and processed by CNC machines and other equipment, and customized design can be carried out according to actual needs to meet the decoration requirements of different places.

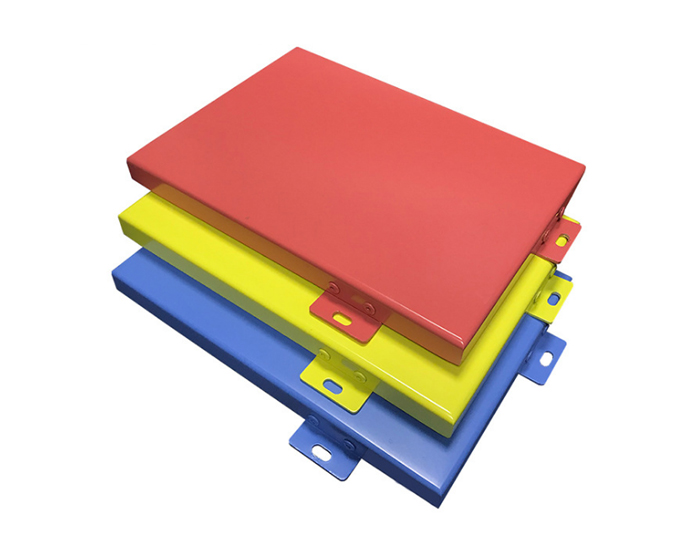

2. Surface treatment

2mm aluminum veneer can be surface treated through anodizing, spraying, and other methods to enhance the artistic and aesthetic appeal of the fixture.

3. Welding installation

2mm aluminum veneer can be installed by welding or other methods to ensure the firmness and stability of the fixture.

3、 Application Fields

1. Industrial plant

2mm aluminum veneer can be used in the construction of industrial plants as decorative materials for roofs, walls, floors, etc., to improve the insulation effect of the plant and further save energy.

2. Commercial buildings

2mm aluminum veneer can be used in the construction of commercial buildings as decorative materials for ceilings, walls, floors, etc., increasing the artistic and aesthetic sense of commercial buildings.

3. Transportation facilities

2mm aluminum veneer can be used for the construction of transportation facilities, such as wall and ceiling decorations in subway stations, airports, and other places, to improve the aesthetics and comfort of the venue.

4、 Summary

2mm aluminum veneer has unique advantages in tooling design and manufacturing processes, including lightweight design, good corrosion resistance, and high compressive strength. In the future development, we should strengthen technological research and improvement, promote the concept of green buildings, adopt more environmentally friendly and sustainable building materials and technologies, and jointly build beautiful homes.

Customer service QQ

Customer service QQ