Industry information

Company News

- Aluminum veneer: the "light luxury" coat of modern architecture

- Modern interpretation of carved aluminum veneer: the art of time carving

- Ancient charm and modern style, carved aluminum veneer interprets the beauty of modern architecture

- Punched aluminum veneer: the fashionable choice for modern architecture?

- Punched aluminum veneer: the new favorite of fashionable architecture, revealing its charm!

Industry dynamics

- Carved aluminum veneer, an artistic window in modern architecture

- Space saving punched aluminum veneer

- Exquisite craftsmanship, beautiful encounter of carved aluminum veneer

- Can the insulation function of aluminum veneer extend the service life of buildings?

- Exploring the production process of aluminum veneer manufacturers

Frequently asked questions

- What is the sales market for aluminum veneer?

- How to improve the product quality and performance of aluminum veneer?

- What are the applications of aluminum veneer in architectural decoration?

- What safety issues should be paid attention to in the production and manufacturing of aluminum veneer?

- What is the environmental performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

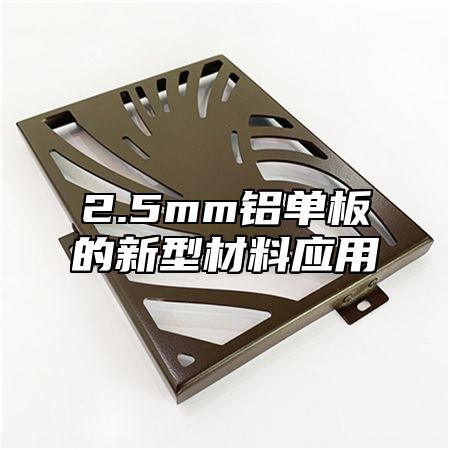

Application of new materials for 2.5mm aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-15 02:20:16

- Click:0

Aluminum veneer, as a lightweight and weather resistant building material, has a wide range of applications in architectural decoration. And 2.5mm thick aluminum veneer is a common specification, and the application of its new material is also one of the important factors affecting its application effect. The following will provide a detailed introduction to the new material application of 2.5mm thick aluminum veneer.

1、 Types of new materials

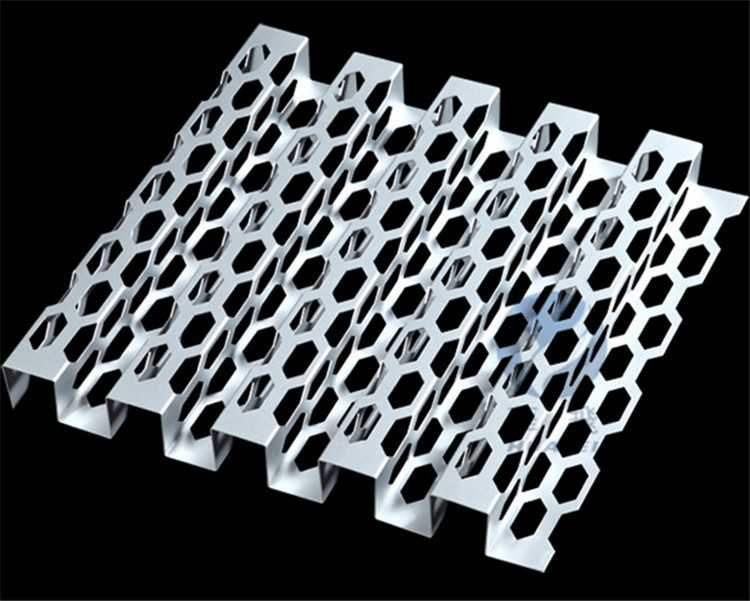

At present, common new materials for 2.5mm thick aluminum veneer in the market include honeycomb aluminum plate, corrugated aluminum plate, color coated aluminum plate, etc.

1. Honeycomb aluminum plate: Made of high-strength aluminum alloy sheet as raw material, it is extruded through molds to form a honeycomb structure, which has the characteristics of lightweight, high strength, sound insulation, and heat insulation. It is suitable for large building curtain walls and other occasions.

2. Corrugated aluminum plate: Made of high-strength aluminum alloy plate as raw material, processed by rolling and embossing technology to form a corrugated structure, it has the characteristics of lightweight, high strength, fire resistance, corrosion resistance, etc., and is suitable for indoor and outdoor decoration, advertising boards and other fields.

3. Color coated aluminum plate: High strength aluminum alloy plate is used as the raw material, which is pre treated and surface coated to form various colored coatings. It has the characteristics of high aesthetics and good corrosion resistance, and is suitable for indoor and outdoor decoration, advertising boards and other fields.

2、 Advantages of new materials

1. Improve product performance: The application of new materials can enhance product performance, such as strength, sound insulation, heat insulation, and other properties.

2. Enhance product aesthetics: The application of new materials can enhance the aesthetics of products, making them more in line with market demand and aesthetic standards.

3. Improve product added value: The application of new materials can increase the added value of products and enhance the market competitiveness of enterprises.

3、 Precautions

When applying new materials for 2.5mm thick aluminum veneer, the following points should be noted:

1. Operators need to possess certain skills and experience to ensure the correct application and quality assurance of new materials.

2. It is necessary to select suitable new materials according to different needs and requirements, and make reasonable combinations and uses.

3. During the production and manufacturing process, it is important to maintain stable production processes and quality standards to ensure the quality and performance of new materials.

4. During installation and use, attention should be paid to safety and details to ensure that new materials can be installed and used according to requirements.

4、 Summary

The application of new materials such as 2.5mm thick aluminum veneer is one of the effective means to meet different needs. When applying new materials, it is necessary to pay attention to selecting suitable materials, maintaining stable production processes and quality standards to ensure the correct application and quality assurance of new materials. At the same time, it can also be reasonably matched and used according to market demand and aesthetic standards to enhance the beauty and added value of the product.

- previous page:Price of 2.5mm thick aluminum veneer

- Next page:Fixture design and manufacturing process for 2mm aluminum veneer

Customer service QQ

Customer service QQ