Corporate News

Company News

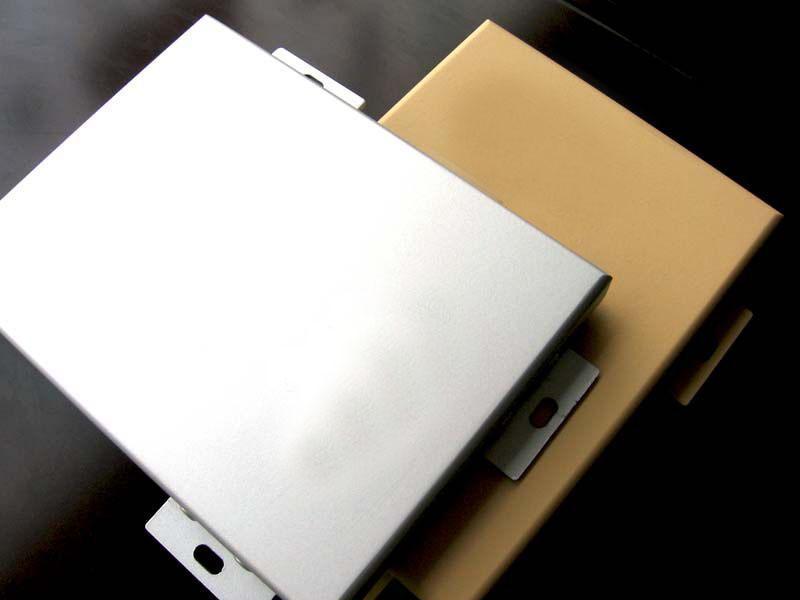

- Fluorocarbon aluminum veneer: the new darling of architectural aesthetics

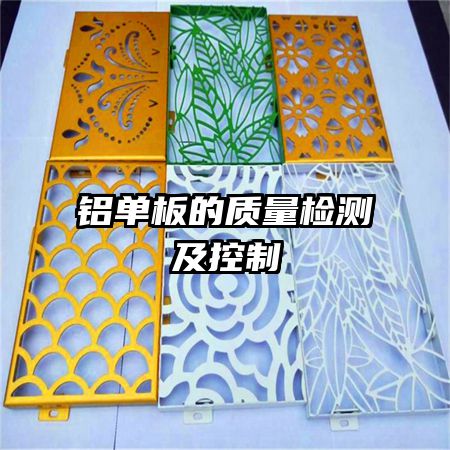

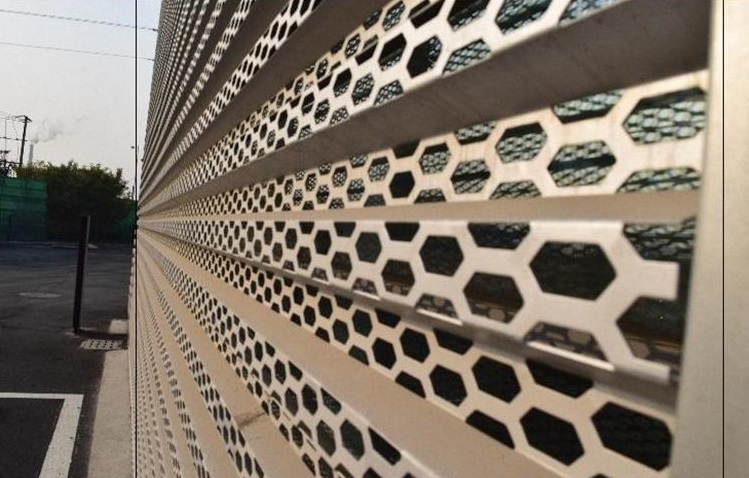

- Punched aluminum veneer: a perfect fusion of innovation and aesthetics

- Fluorocarbon aluminum veneer: the "fashionable coat" of modern architecture

- Ancient Charm and New Trend: The Fashion Evolution Theory of Carved Aluminum Veneer

- The fashionable charm of punched aluminum veneer creates a new highlight of modern space

Industry dynamics

- Advantages of aluminum veneer application in earthquake prone areas

- Manufacturing process and production technology of 2.5mm aluminum veneer for ceiling

- Ancient charm and modern style, carved aluminum veneer interprets modern beauty

- Unveiling the "face saving" charm of fluorocarbon aluminum veneer

- Material selection guide for indoor ceiling aluminum veneer

Frequently asked questions

- What are the applications of aluminum veneer in architectural decoration?

- What safety issues should be paid attention to in the production and manufacturing of aluminum veneer?

- What conditions are required for the production of aluminum veneer?

- What is the processing and manufacturing process of aluminum veneer?

- What is the environmental performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

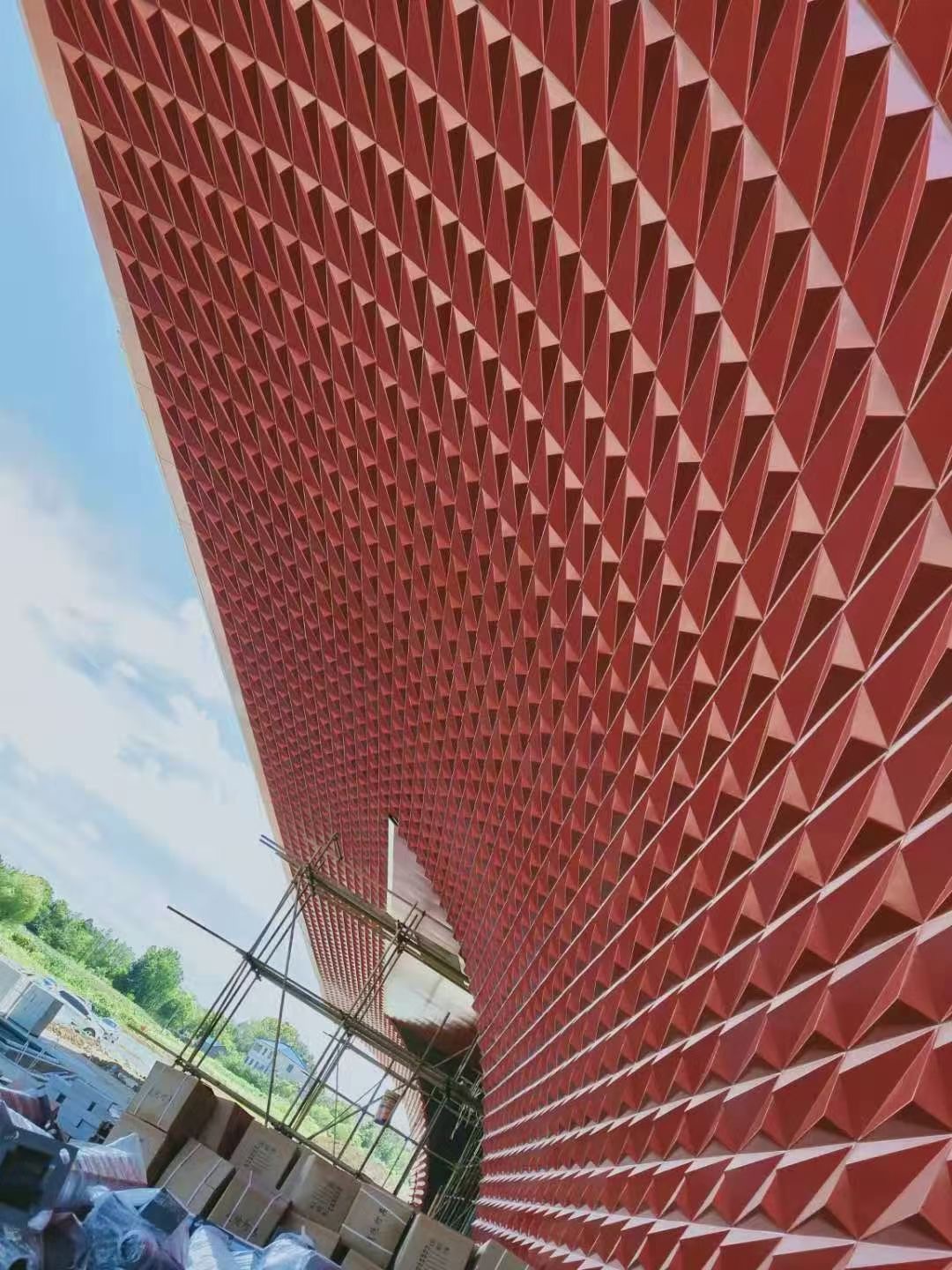

Quality inspection and control of aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: February 25, 2025 23:12:00

- Click:0

1、 Raw material selection

1. Qualified supplier

Choosing qualified suppliers is the first step in ensuring the quality of aluminum veneer. Qualified suppliers should have mature production processes and technologies, and be able to provide raw materials that meet standard requirements.

2. Raw material testing

Conduct comprehensive testing on the purchased raw materials, including chemical composition analysis, mechanical property testing, etc. Only by ensuring the stable and reliable quality of raw materials can the quality of the final product be guaranteed.

3. Control the quality of raw material procurement

Establish a comprehensive supply chain management system to ensure controllable quality of raw material procurement. To establish long-term stable cooperative relationships with suppliers and strengthen the management and supervision of suppliers.

2、 Production process control

1. Production process specification

Establish strict production process standards, clarify quality requirements and operating procedures for each link. Including various processes such as raw material processing, molding, surface treatment, etc., to ensure the controllability of the entire production process.

2. Equipment management

Regularly maintain and repair production equipment to ensure its normal operation. And equipped with advanced production equipment to improve production efficiency and product quality.

3. Employee training

Strengthen training on production processes, improve employees' operational skills and quality awareness. Regularly organize technical exchanges and training to continuously improve the professional level of employees.

3、 Strict quality inspection

1. Raw material inspection

Conduct a comprehensive quality inspection of the purchased raw materials, including visual inspection, dimensional testing, chemical composition analysis, etc. Only qualified raw materials can enter the next process.

2. Process monitoring

Conduct comprehensive monitoring during the production process, including product size, surface quality, coating effect, etc. Timely identify problems and make adjustments to ensure stable product quality.

3. Finished product inspection

Conduct a comprehensive inspection of the final product, including visual inspection, mechanical performance testing, weather resistance testing, etc. Only qualified products can be sold from the factory.

4、 Comprehensive after-sales service

1. Quality traceability

Establish a comprehensive quality traceability system, record every product, and promptly handle customer complaints and quality issues. Ensure product quality traceability and improve after-sales service quality.

2. Customer satisfaction survey

Regularly conduct customer satisfaction surveys to understand customers' evaluations and needs for product quality, and promptly improve any shortcomings. Improve customer satisfaction and enhance brand competitiveness.

3. Continuous improvement

Continuously summarize experience and carry out continuous improvement of quality management. Learn from the advanced experience of other industries, strengthen internal management, improve product quality and corporate competitiveness.

5、 Summary:

The quality inspection and control of aluminum veneer are crucial for ensuring stable product quality and customer satisfaction. Only by striving for excellence in raw material selection, production process control, strict quality inspection, and comprehensive after-sales service can high-quality aluminum veneer products be produced to meet customer needs.

Customer service QQ

Customer service QQ