Industry information

Company News

- Customize aluminum veneer to create a new trend of personalized space!

- Fluorocarbon aluminum veneer: a modern interpretation of architectural aesthetics

- Fluorocarbon aluminum veneer: the "fashionable coat" of modern architecture

- Fluorocarbon aluminum veneer: a rising star in the aluminum industry and a star material in the construction industry

- Carved aluminum veneer: a fashionable choice for modern architecture

Industry dynamics

- Aluminum veneer customization, creating a new trend of personalized home decor!

- Aluminum veneer curtain wall: the "fashionable coat" of modern architecture

- Aluminum veneer customization: an artistic journey to create personalized spaces

- Fluorocarbon aluminum veneer: a fashionable outerwear for modern architecture

- Aluminum veneer curtain wall, the fashionable outerwear of modern architecture

Frequently asked questions

- What is the processing and manufacturing process of aluminum veneer?

- What is the environmental performance of aluminum veneer?

- What is the future market development trend of aluminum veneer?

- How to improve the product quality and performance of aluminum veneer?

- What are the applications of aluminum veneer in architectural decoration?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Manufacturing process and production technology of 2.5mm aluminum veneer for ceiling

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: February 26, 2025 18:23:51

- Click:0

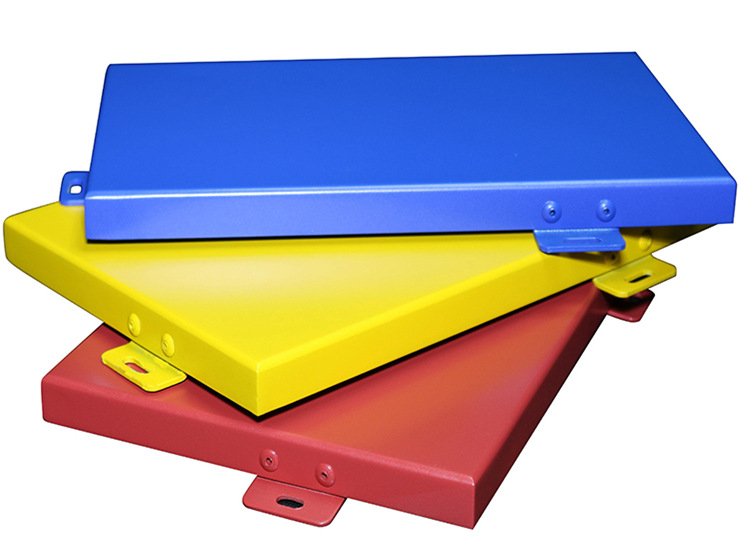

2.5mm aluminum veneer ceiling is a new type of building material with characteristics such as lightweight, high strength, and corrosion resistance. The manufacturing process and production technology are crucial for ensuring the quality and performance of the product. This article will provide a detailed introduction to the manufacturing process and production technology of 2.5mm aluminum veneer for ceilings.

1、 Production process

1. Raw material preparation

The main raw material for 2.5mm aluminum veneer ceiling is high-strength aluminum alloy sheet. Strict inspection and screening of raw materials are required before production to ensure that they meet product quality requirements.

2. Cutting and processing

Cut and process the raw materials according to the design requirements to obtain the required size and shape. This step requires the use of professional cutting equipment and technology to ensure cutting accuracy and surface quality.

3. Bending processing

Bend the cut aluminum veneer to meet different architectural decoration needs. This step requires the use of professional bending equipment and technology to ensure bending accuracy and surface quality.

4. Welding processing

Weld the bent aluminum veneer to form a complete aluminum veneer ceiling. This step requires the use of professional welding equipment and techniques to ensure welding strength and surface quality.

5. Surface treatment

Surface treatment of welded aluminum veneer, including anodizing, spraying and other processes, to improve its corrosion resistance and aesthetics. This step requires the use of professional surface treatment equipment and technology to ensure surface quality and performance.

2、 Production Technology

1. Automated production line

Modern 2.5mm aluminum veneer production adopts automated production lines, which can achieve full process automation control from raw material procurement to finished product delivery. This can not only improve production efficiency and product quality, but also reduce production costs and labor input.

2. Precision equipment and technology

The production of modern 2.5mm aluminum veneer requires the use of precision mechanical equipment and technology, including CNC machine tools, laser cutting machines, anodizing equipment, etc. The accuracy and stability of these devices are crucial for ensuring product quality and performance.

3. Strict quality control system

The production enterprise of 2.5mm aluminum veneer for ceiling needs to establish a sound quality control system, including raw material inspection, production process control, and finished product testing. Only through strict quality control can the quality and performance of the product be guaranteed.

The manufacturing process and production technology of 2.5mm aluminum veneer for ceiling are crucial for ensuring product quality and performance. With the continuous advancement of technology and the increasing demand for architectural decoration, we believe that the production technology and manufacturing process of 2.5mm aluminum veneer for ceilings will continue to innovate and improve.

Customer service QQ

Customer service QQ