Corporate News

Company News

- Fluorocarbon aluminum veneer: a perfect combination of fashion and durability

- Ancient charm and modern style carved aluminum veneer: an artistic treasure in the aluminum industry

- Ancient charm and modern style, an artistic journey of carved aluminum veneer

- The fashion revolution of aluminum veneer: not just on the surface

- The charm of aluminum veneer: it's not just about being lightweight!

Industry dynamics

- Economic analysis of aluminum veneer prices

- Analysis of Construction Precautions for Fluorocarbon Aluminum Single Panel Ceiling

- 2. Customize aluminum veneer to give your home a brand new look Aluminum veneer customization, personalized decoration

- What is the cost-effectiveness of aluminum veneer?

- Customized production process of aluminum veneer

Frequently asked questions

- What are the applications of aluminum veneer in architectural decoration?

- What factors affect the production and sales of aluminum veneer?

- What safety issues should be paid attention to in the production and manufacturing of aluminum veneer?

- What is the future market development trend of aluminum veneer?

- What is the sales market for aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Surface treatment technology and development trend of aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-02-24 04:03:02

- Click:0

Surface treatment technology and development trend of aluminum veneer

Abstract: This article will elaborate on the surface treatment technology and development trends of aluminum veneer from four aspects, including coating technology, oxidation treatment technology, sandblasting treatment technology, and anodizing technology.

1、 Coating technology

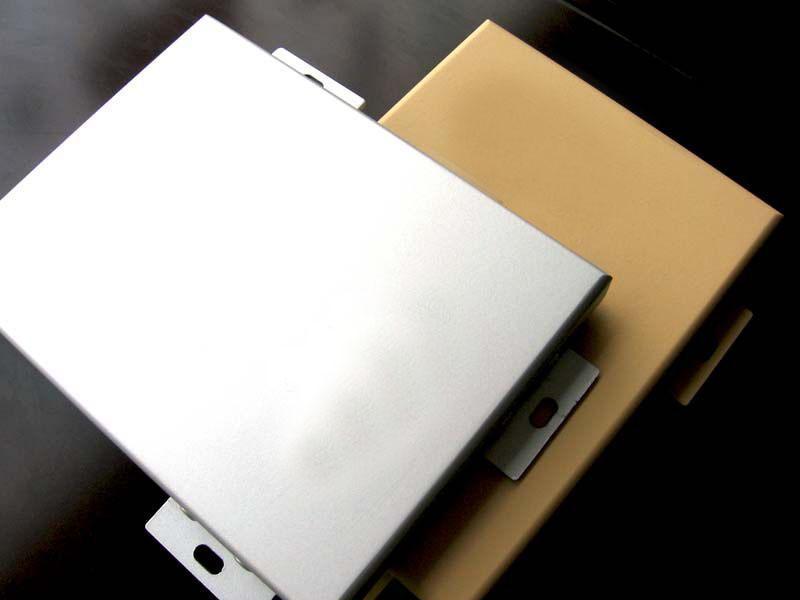

1. Protection in natural environment: Aluminum veneer can be protected in natural environment through coating technology. The commonly used types of coatings include anti-corrosion coatings, dust-proof coatings, and UV resistant coatings.

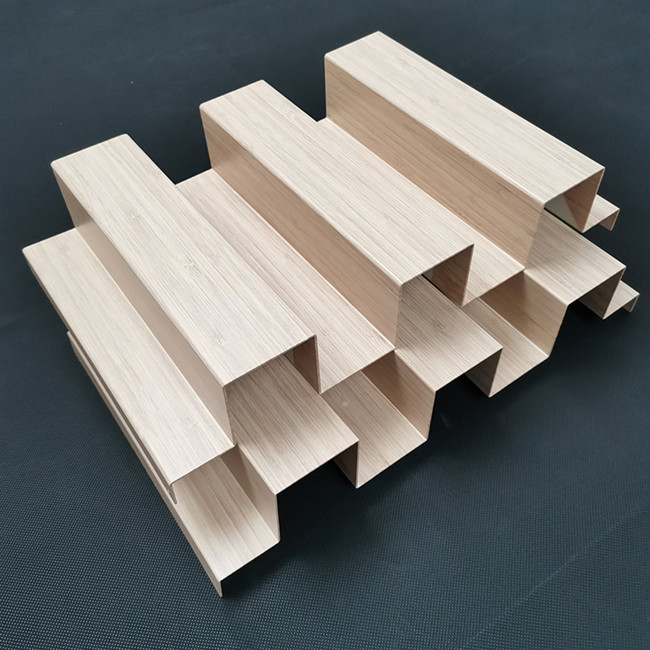

2. Enhanced decorative effect: Not only can it protect aluminum veneer, but coating technology can also give it various decorative effects. Such as stone grain effect, wood grain effect, etc., make the application of aluminum veneer more diversified.

3. The improvement of sustainability and environmental friendliness: Currently, coating technology is developing towards a more environmentally friendly and sustainable direction. Develop coatings using renewable materials to reduce environmental impact.

2、 Oxidation treatment technology

1. Improving corrosion resistance: Oxidation treatment technology is one of the important methods for surface treatment of aluminum veneer, which can enhance its corrosion resistance. During the oxidation process, a dense oxide film is formed on the surface of the aluminum veneer, effectively isolating it from external corrosive substances.

2. Improving color and gloss: Not only can it enhance corrosion resistance, but oxidation treatment can also improve the color and gloss of aluminum veneer. By adjusting the oxidation process conditions, aluminum oxide veneers with different colors and glossiness can be obtained.

3. Energy saving and environmental protection: Compared with other surface treatment methods, oxidation treatment technology does not require the use of organic solvents and coatings, and has the characteristics of energy saving and environmental protection.

3、 Sandblasting treatment technology

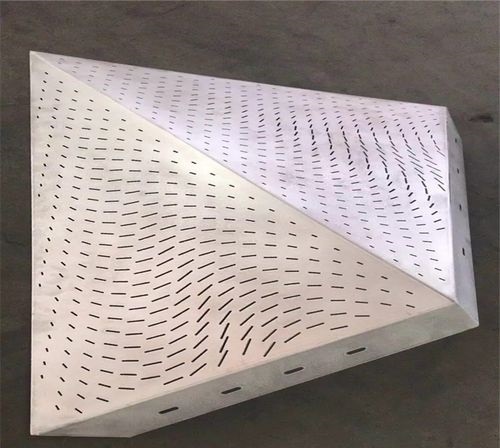

1. Increasing roughness: Sandblasting treatment technology can increase the surface roughness of aluminum veneer, thereby enhancing adhesion and slip resistance.

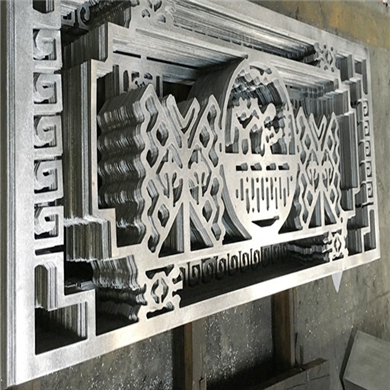

2. Improving visual effects: By using sand particles of different sizes and materials for sandblasting treatment, various textures and patterns can be formed on the surface of aluminum veneer, thereby improving its visual effect.

3. Easy to maintain: The sandblasted aluminum veneer surface is easier to clean and maintain, reducing maintenance costs.

4、 Anodizing technology

1. Improving hardness and durability: Anodizing technology is a method of transforming the surface of aluminum veneer into an aluminum oxide layer. The aluminum oxide layer has high hardness and durability, which can effectively extend the service life of aluminum veneer.

2. Increasing color selection: By adjusting the anodizing process parameters, different colored aluminum oxide layers can be obtained, further enriching the color selection of aluminum veneer.

3. Superior environmental performance: Anodizing technology does not require the use of organic solvents and coatings, making it more environmentally friendly and in line with the requirements of sustainable development.

5、 Summary:

With the rapid development of the construction industry, aluminum veneer has been widely used as a lightweight, high-strength, and corrosion-resistant building material. The surface treatment technology of aluminum veneer continues to develop, with coating technology, oxidation treatment technology, sandblasting treatment technology, and anodizing technology becoming mainstream. These technologies not only protect aluminum veneers, but also provide rich decorative effects and better environmental performance. In the future, with the advancement of technology and the continuous changes in demand, the surface treatment technology of aluminum veneer will become more diversified and innovative, meeting the needs of different industries.

Customer service QQ

Customer service QQ