Industry information

Company News

- Customized aluminum veneer, a new choice for personalized space

- Aluminum veneer customization, creating a new trend of personalized space

- Carved aluminum veneer: a delicate interpretation of modern architecture

- New chapter in ancient charm: The magnificent transformation of carved aluminum veneer

- Fluorocarbon aluminum veneer: the fashionable new darling of the aluminum industry

Industry dynamics

- Aluminum veneer: the green new darling of the construction industry

- Fluorocarbon aluminum veneer: the fashionable choice for modern architecture?

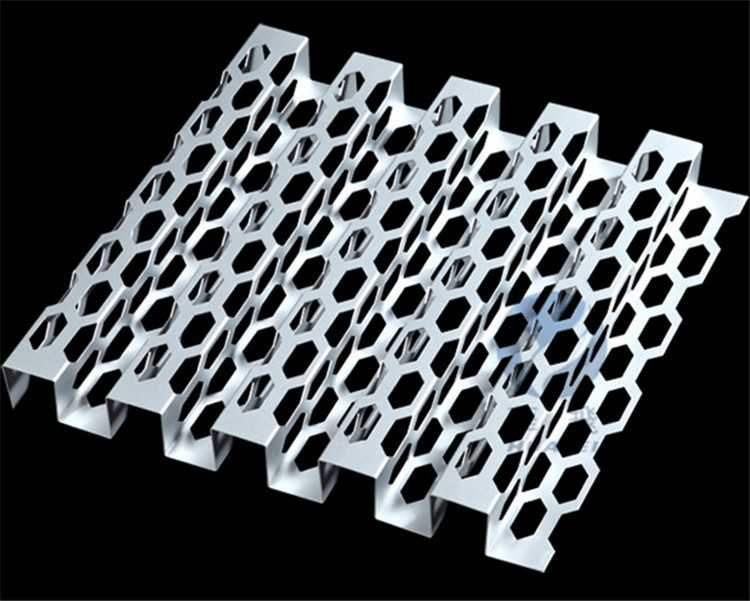

- Carved aluminum veneer: a unique decoration in modern architecture

- Analysis of the advantages and disadvantages of curved ceiling aluminum veneer

- Curtain wall aluminum veneer: the beauty of architecture, the light of aluminum materials

Frequently asked questions

- What factors affect the production and sales of aluminum veneer?

- What is the sales market for aluminum veneer?

- What is the processing and manufacturing process of aluminum veneer?

- What is the environmental performance of aluminum veneer?

- What conditions are required for the production of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

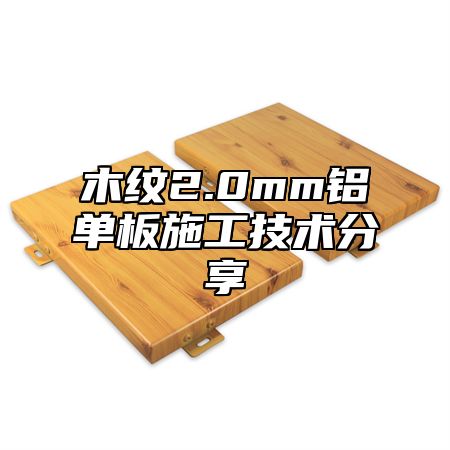

Construction technology sharing of wood grain 2.0mm aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: March 1, 2025 05:51:37

- Click:0

Wood grain 2.0mm aluminum veneer is a new type of building material that presents a wood like texture on its surface, with advantages such as beauty, environmental friendliness, and durability. During the construction process, correct installation methods and techniques can ensure the quality and performance of aluminum veneer. Now let's share the construction technology of wood grain 2.0mm aluminum veneer.

1、 Preparation work

1. Material preparation

Before construction, it is necessary to prepare the required materials and tools, including wood grain 2.0mm aluminum veneer, keel, corner brackets, screws, drills, cutting machines, etc.

1. On site inspection

Before construction, it is necessary to inspect the construction site, including ground flatness, wall verticality, etc., to ensure that the subsequent installation work can proceed smoothly.

2、 Installation steps

1. Install the keel

Install the keel on the wall or ceiling according to the design requirements, and adjust it with a level to achieve the required levelness.

1. Install corner code

Install corner brackets on the keel to fix the wood grain 2.0mm aluminum veneer. It should be noted that the installation position of the corner code should be accurate and ensure that the distance between each corner code is consistent.

1. Install wood grain 2.0mm aluminum veneer

Place the wood grain 2.0mm aluminum veneer on the corner bracket according to the design requirements and fix it with screws. It should be noted that the installation direction of the aluminum veneer should be consistent with the direction of the keel, and the gap between the aluminum veneer and the wall should be uniform.

3、 Precautions

1. Safety first

During the construction process, it is necessary to pay attention to safety issues, such as wearing protective equipment such as goggles and gloves, as well as complying with relevant safety operating procedures.

1. Pay attention to material quality

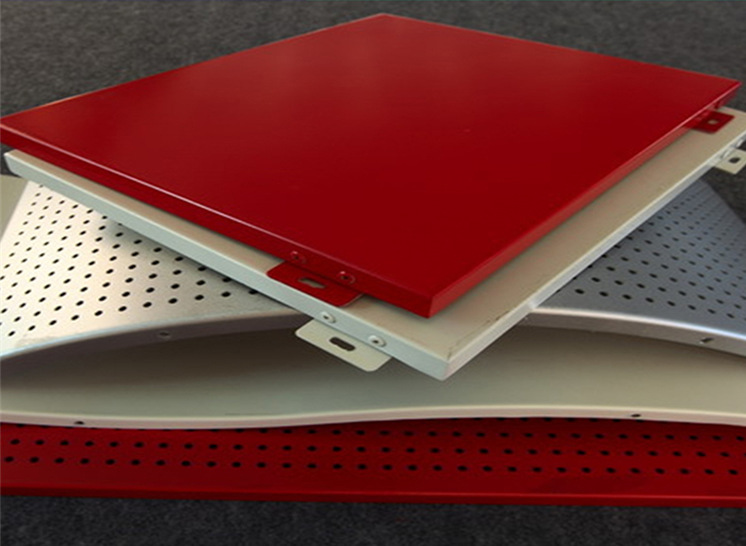

When selecting materials, attention should be paid to quality issues, especially whether the thickness and strength of aluminum veneer meet the requirements. At the same time, attention should be paid to whether the anti rust and anti-corrosion treatment of the materials is in place.

1. Pay attention to construction details

Attention should be paid to details during the construction process, such as the number and position of corner brackets, the installation direction of aluminum veneers, etc., which will affect the final decorative effect.

Customer service QQ

Customer service QQ