Industry information

Company News

- The Fashion Transformation of Aluminum Veneer: A Gorgeous Counterattack from Factory to Home Furnishings

- Modern interpretation of carved aluminum veneer: the art of time carving

- Aluminum veneer customization: personalized space, separated by one board

- Aluminum veneer curtain wall, the secret behind the beauty of architecture

- Aluminum veneer: a modern interpretation of industrial aesthetics

Industry dynamics

- How to control the production cost of aluminum veneer?

- Construction technology sharing of wood grain 2.0mm aluminum veneer

- Improvement and Innovation of Production Process for Aluminum Veneer

- Analysis of Construction Precautions for Fluorocarbon Aluminum Single Panel Ceiling

- Analysis of the Industry Prospects for Aluminum Veneer Prices

Frequently asked questions

- What are the applications of aluminum veneer in architectural decoration?

- What is the processing and manufacturing process of aluminum veneer?

- What are the product characteristics of aluminum veneer?

- How to improve the product quality and performance of aluminum veneer?

- What safety issues should be paid attention to in the production and manufacturing of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the manufacturing process of aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: March 11, 2025 11:07:28

- Click:0

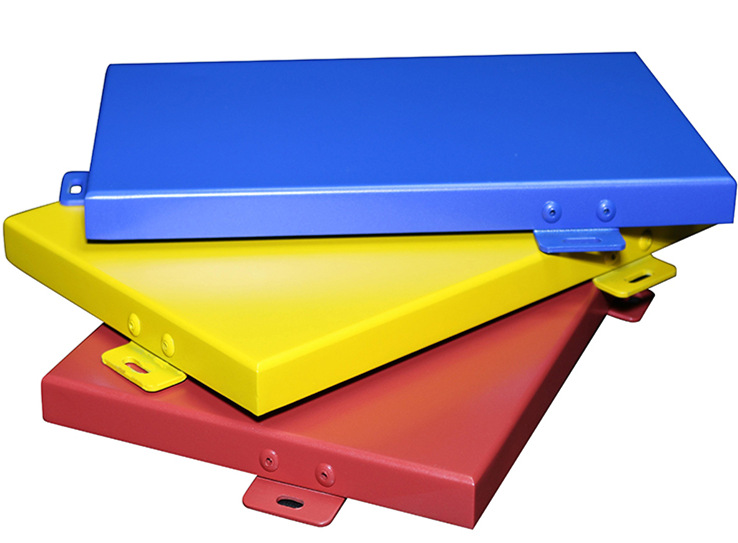

Aluminum veneer is a common building material, and its manufacturing process includes multiple steps such as raw material preparation, cutting, bending, punching, and welding. Below, we will provide a detailed introduction to the manufacturing process of aluminum veneer.

1. Raw material preparation

The main raw materials for aluminum veneer are aluminum alloy sheets and surface treatment agents. Aluminum alloy sheets are usually made of series such as 1100, 3003, 5052, among which the 1100 series is the most common. Surface treatment agents can be fluorocarbon coatings, polyester coatings, powder coatings, etc. Choose different surface treatment agents according to different applications and requirements.

1. Cutting

The cutting of aluminum veneer is the first step in the production process and requires the use of professional cutting equipment. Generally speaking, the thickness of aluminum veneer ranges from 1.5mm to 4.0mm, and adjustments need to be made according to actual needs during cutting. After cutting, the edges need to be chamfered to ensure smooth and burr free edges.

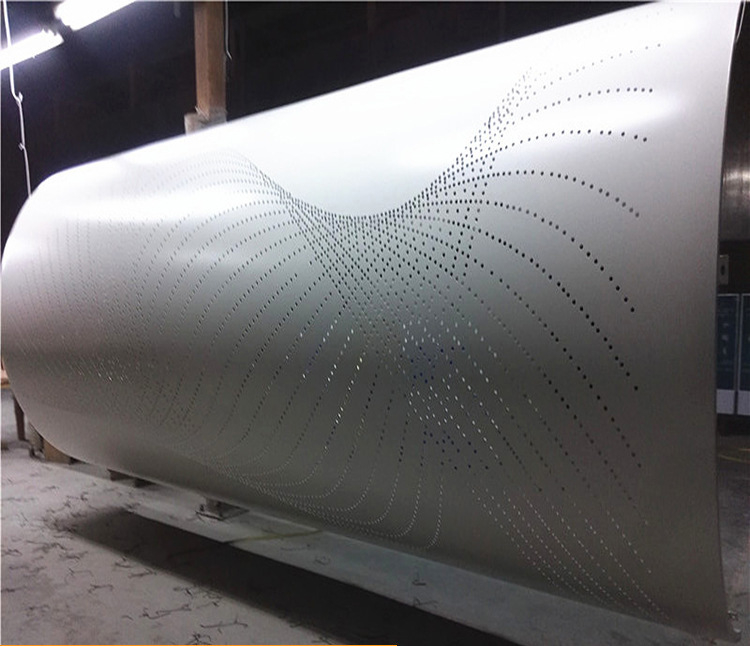

1. Bending

The bending of aluminum veneer is the second step in the manufacturing process, which requires the use of professional bending equipment. When bending, attention should be paid to the angle and direction of the aluminum veneer to ensure that the bent aluminum veneer meets the design requirements. Generally speaking, the angle of aluminum veneer is within 90 degrees, and the direction can be horizontal or vertical.

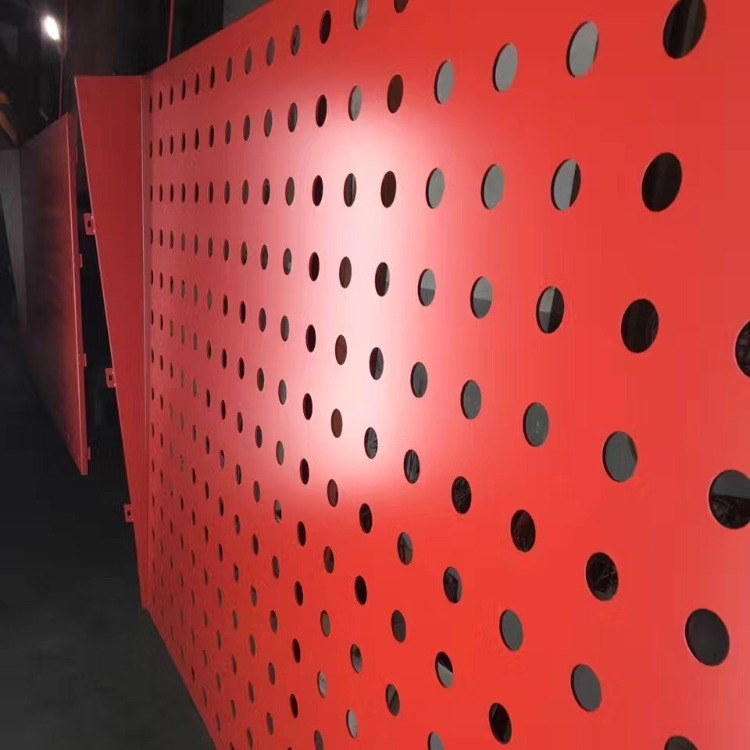

1. Punching holes

The punching of aluminum veneer is the third step in the production process, which requires the use of professional punching equipment. When drilling holes, attention should be paid to the position and size of the holes to ensure that they meet the design requirements. Generally speaking, the aperture of aluminum veneer is between 2mm and 8mm, and the number and position of the holes need to be adjusted according to actual needs.

1. Welding

The welding of aluminum veneer is the final step in the production process and requires the use of professional welding equipment. Attention should be paid to the quality and strength of welding to ensure the stability and safety of aluminum veneer. Generally speaking, there are two welding methods for aluminum veneer: manual welding and machine welding, and different welding methods should be selected according to actual needs.

The production process of aluminum veneer requires multiple steps, including raw material preparation, cutting, bending, punching, welding, and other processes. Designers need to select suitable aluminum veneer materials, colors, textures, and other parameters based on specific application scenarios and design requirements, and strictly follow the production process to achieve the best decorative effect and economic benefits.

Customer service QQ

Customer service QQ