Industry information

Company News

- Fluorocarbon aluminum veneer: innovative building materials, lighting up a new chapter in architectural aesthetics

- Surface treatment and color selection of aluminum veneer

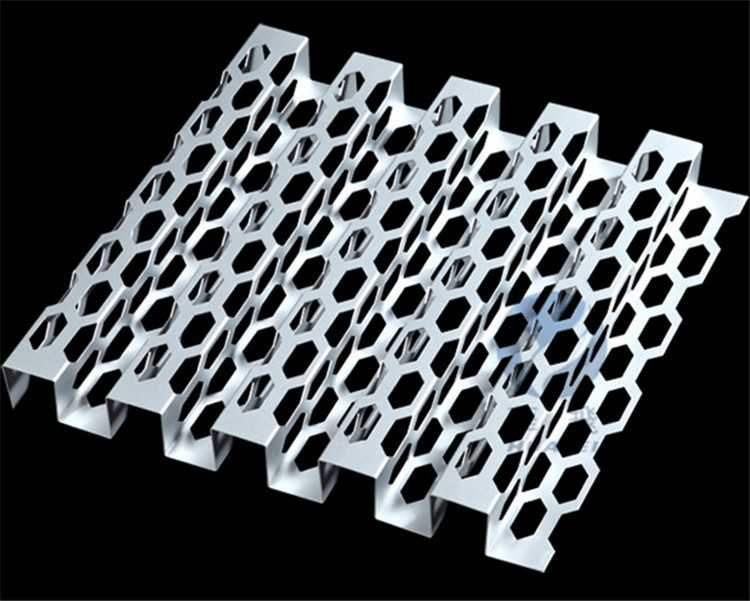

- Carved aluminum veneer: the finishing touch of modern architecture

- Curtain wall aluminum veneer: the fashionable "coat" of modern architecture

- 2. The perfect fusion of classical and modern - Unveiled carved aluminum veneer 3 The invisible craftsman

Industry dynamics

- The new favorite of exterior wall decoration, aluminum veneer, is coming!

- Material selection and performance analysis of aluminum panel curtain wall

- Aluminum veneer curtain wall: an aesthetic revolution in modern architecture

- What is the application scope of aluminum veneer?

- Global market comparison of aluminum veneer prices

Frequently asked questions

- How to improve the product quality and performance of aluminum veneer?

- What safety issues should be paid attention to in the production and manufacturing of aluminum veneer?

- What is the processing and manufacturing process of aluminum veneer?

- What are the applications of aluminum veneer in architectural decoration?

- What is the environmental performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the installation process of aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: March 3, 2025 05:37:15

- Click:0

Aluminum veneer, as a commonly used building material, its installation process is one of the key factors to ensure its effectiveness and lifespan. The following will provide a detailed introduction to the installation process and precautions for aluminum veneer.

1. Preparation work

Before installing the aluminum veneer, some preparatory work is required, including:

(1) Measurement dimensions: Accurately measure the dimensions of aluminum veneer based on architectural design drawings and actual site conditions.

(2) Develop a plan: Based on measurement results and design requirements, develop an installation plan for aluminum veneer, including installation methods, support structures, etc.

(3) Preparation tools: Prepare the necessary tools and equipment, such as drills, screwdrivers, corner codes, level gauges, etc.

1. Install the keel

The installation of aluminum veneer requires the installation of keel first to ensure the stability and flatness of the aluminum veneer. The specific steps for installing the keel are as follows:

(1) Determine the position and quantity of the keel, and arrange it according to the design requirements.

(2) Use an electric drill to drill holes on the ground, then place the keel into the holes and secure it with screws.

(3) Check the flatness and verticality of the keel to ensure it meets the design requirements.

1. Install aluminum veneer

After completing the installation of the keel, you can start installing the aluminum veneer. The specific steps are as follows:

(1) Place the aluminum veneer onto the keel according to the design requirements.

(2) Use corner brackets to fix the aluminum veneer onto the keel, ensuring that the number and position of corner brackets meet the design requirements.

(3) Use a level to check the flatness and verticality of the aluminum veneer, and make necessary adjustments.

1. Closing work

After completing the installation of the aluminum veneer, some finishing work is still needed, including:

(1) Clean up the site: Remove the garbage and debris generated during the construction process.

(2) Quality inspection: Check whether the flatness, verticality, surface quality, etc. of the aluminum veneer meet the design requirements.

(3) Acceptance and delivery: After passing the acceptance inspection, the aluminum veneer will be delivered to the owner or user unit.

Customer service QQ

Customer service QQ