Industry information

Company News

- The magnificent transformation of aluminum veneer: not only as a building material, but also as a representation of art

- Fluorocarbon aluminum veneer: low-key luxury in the construction industry

- How much do you know about aluminum veneer: an elegant choice for modern architecture?

- Unveiling punched aluminum veneer: the fashionable new favorite in light luxury building materials

- Aluminum veneer: a fashionable choice in modern architecture

Industry dynamics

- Aluminum veneer manufacturers provide personalized customization to meet your needs

- Carved aluminum veneer: exquisite silhouette of architectural art

- Innovative application of wood grain aluminum curtain wall in architectural design

- Aluminum veneer curtain wall: an innovator in architectural aesthetics

- Punched aluminum veneer: a new trend in aluminum materials, creating personalized spaces

Frequently asked questions

- How to improve the product quality and performance of aluminum veneer?

- What safety issues should be paid attention to in the production and manufacturing of aluminum veneer?

- What is the processing and manufacturing process of aluminum veneer?

- What are the applications of aluminum veneer in architectural decoration?

- What is the environmental performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Can fluorocarbon aluminum veneer be processed for curved surfaces?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: February 26, 2025 16:58:31

- Click:0

As a building material, the surface processing ability of fluorocarbon aluminum veneer is one of the important concerns for consumers. The following will provide a detailed introduction on whether fluorocarbon aluminum veneer can be processed into curved surfaces.

1. Material characteristics

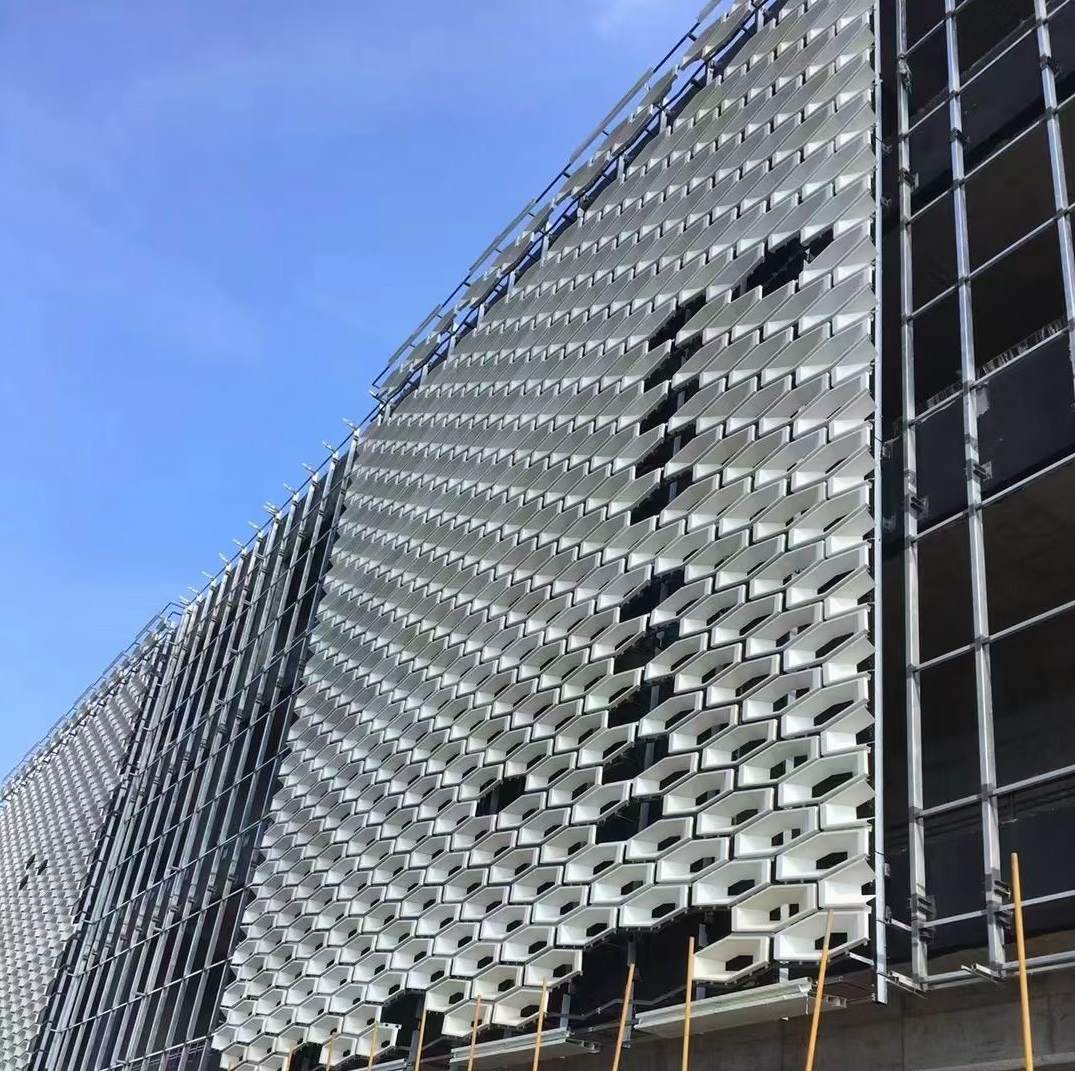

Fluorocarbon aluminum veneer is mainly composed of metal materials such as aluminum alloy and fluorocarbon coating. Compared to other building materials such as concrete and stone, fluorocarbon aluminum veneer has higher strength and stiffness, and its surface has good corrosion resistance and wear resistance after fluorocarbon coating treatment. These characteristics make fluorocarbon aluminum veneer have strong stability and durability when facing various environmental factors.

1. Surface machining capability

The surface processing capability of fluorocarbon aluminum veneer is closely related to its material properties, structural design, and other factors. Generally speaking, fluorocarbon aluminum veneer can be curved through special processing techniques, such as using CNC machine tools and other equipment. The structural design of fluorocarbon aluminum veneer can also improve its surface processing ability, such as using reinforced cross braces to increase its overall stability and wind resistance.

It should be noted that although fluorocarbon aluminum veneer has a certain degree of curved surface processing ability, its curved surface processing ability is relatively weak, inferior to some building materials specifically used for curved surface processing such as gypsum board, fiberglass, etc. In practical applications, selection and design need to be based on specific circumstances.

Fluorocarbon aluminum veneer can be processed into curved surfaces, but its ability to process curved surfaces is relatively weak. Consumers should choose fluorocarbon aluminum veneer products that meet the standards and follow the manufacturer's instructions and maintenance recommendations to ensure the service life and stable performance of fluorocarbon aluminum veneer. When performing surface machining, it is also necessary to pay attention to the characteristics of the material and the limitations of the structure to ensure that the machining effect meets the requirements.

Customer service QQ

Customer service QQ