Industry information

Company News

- Fluorocarbon aluminum veneer: the new darling of architectural aesthetics

- Craftsmanship, carved aluminum veneer interprets modern home aesthetics

- Punched aluminum veneer: creating a new style of modern architectural aesthetics

- Ancient charm and modern style, an artistic journey of carved aluminum veneer

- Fluorocarbon aluminum veneer: the preferred "light luxury" option for future buildings?

Industry dynamics

- Is the innovative trend of aluminum veneer in architectural exterior design worth paying attention to?

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer, a new chapter in the beauty of industry

- Customized aluminum veneer, creating a new trend of personalized space

- Punched aluminum veneer: the fashionable choice for modern architecture?

Frequently asked questions

- What safety issues should be paid attention to in the production and manufacturing of aluminum veneer?

- What is the future market development trend of aluminum veneer?

- What conditions are required for the production of aluminum veneer?

- What factors affect the production and sales of aluminum veneer?

- What is the processing and manufacturing process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

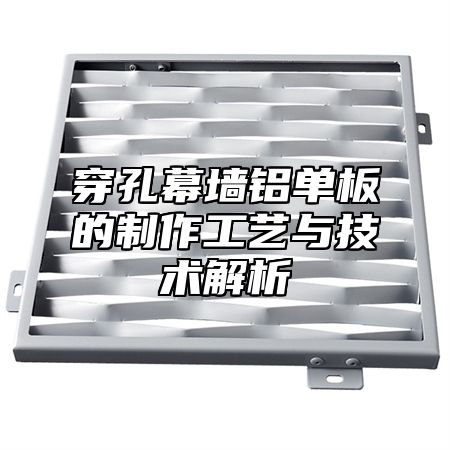

Production process and technical analysis of perforated curtain wall aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-16 19:44:21

- Click:0

Perforated curtain wall aluminum veneer is a new type of building decoration material, and its production process and technology are very unique. The following will analyze the production process and technology of perforated curtain wall aluminum veneer from two aspects.

1、 Production process

The production process of perforated curtain wall aluminum veneer mainly includes the following steps:

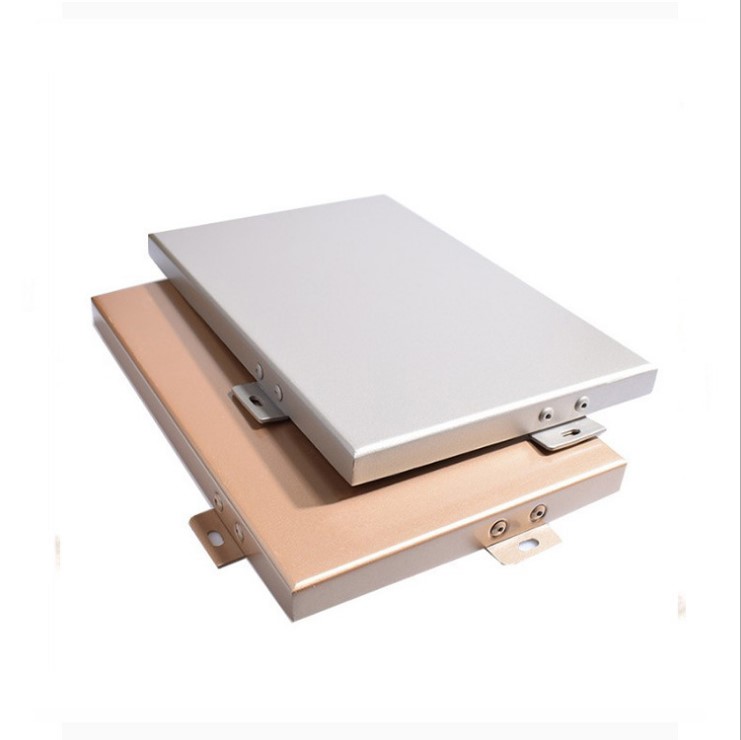

1. Material preparation: Select high-quality aluminum alloy materials as raw materials, and determine the size and thickness of the aluminum plate according to design requirements.

2. CNC cutting: Use a CNC cutting machine to accurately cut aluminum plates to ensure that the size and shape of the aluminum plates meet the design requirements.

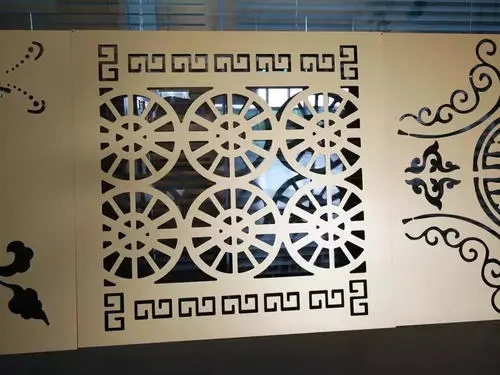

3. Punching processing: Punching processing is performed on aluminum plates to create a perforated and hollow effect. Drilling can be done using laser drilling machines or mechanical drilling machines.

4. Surface treatment: Special treatment is applied to the surface of aluminum plates, such as anodizing, electrophoretic coating, etc., to increase their corrosion resistance and aesthetics.

5. Assembly and installation: Assemble and install perforated aluminum panels according to design requirements to form a complete perforated curtain wall aluminum veneer.

2、 Technical analysis

The technology of perforated curtain wall aluminum veneer mainly includes the following aspects:

1. Perforation technology: Perforation technology is one of the key technologies for producing perforated curtain wall aluminum veneer. By using equipment such as laser drilling machines or mechanical drilling machines, precise perforation effects can be formed on aluminum plates, thereby achieving the design requirements of hollowing out.

2. Surface treatment technology: Surface treatment technology is an important means to improve the appearance quality and corrosion resistance of perforated curtain wall aluminum veneer. Common surface treatment techniques include anodizing, electrophoretic coating, etc., which can effectively increase the corrosion resistance and aesthetics of aluminum plates.

3. Assembly and installation technology: Assembly and installation technology is one of the key technologies to ensure the correct installation and use of perforated curtain wall aluminum panels. Accurate assembly and installation are required according to design requirements to ensure the quality and stability of the entire perforated curtain wall aluminum veneer.

The production process and technology of perforated curtain wall aluminum veneer are very unique, requiring precision machining and processing in multiple stages to complete. In the future, with the continuous development of technology and the increasing demand for architectural decoration, the application prospects of perforated curtain wall aluminum veneer will be even broader.

Customer service QQ

Customer service QQ