Industry information

Company News

- Fluorocarbon aluminum veneer: the 'hidden hero' of the construction industry

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Aluminum veneer: the beauty of industry, simple yet not simple

- Curtain wall aluminum veneer: an aesthetic weapon of modern architecture, revealing the secrets behind it

Industry dynamics

- Aluminum veneer: the fashionable new favorite in the construction industry

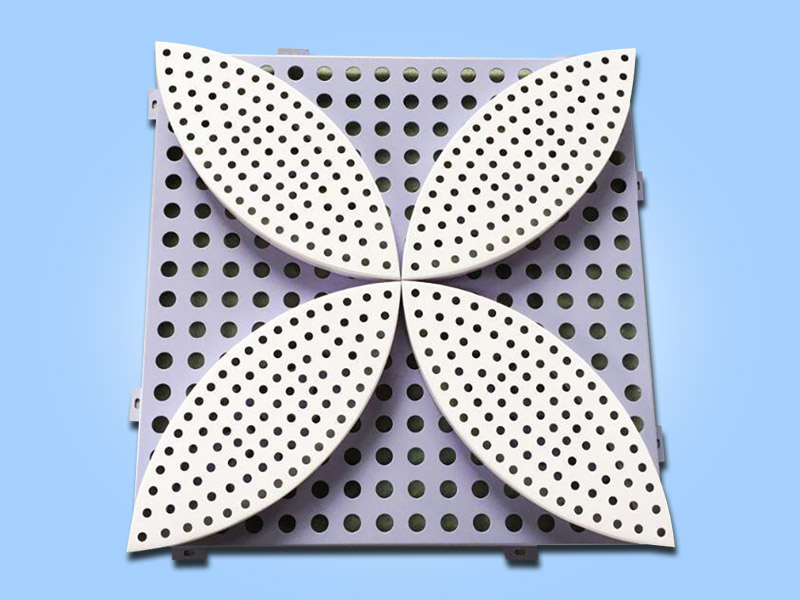

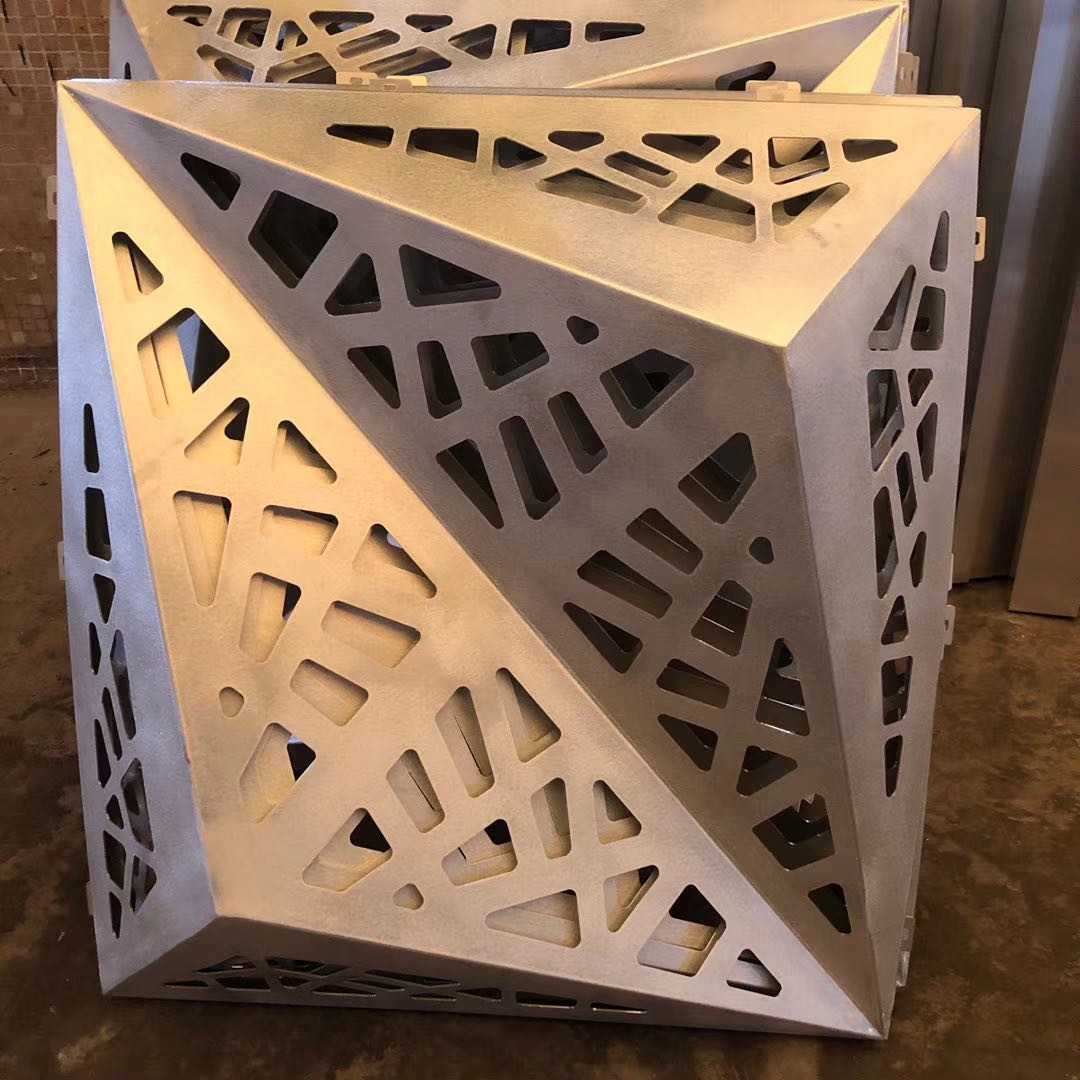

- Punched aluminum veneer: the new favorite of fashionable architecture, a good helper for beautifying the environment!

- Innovative application of stone carved aluminum veneer in architectural decoration

- Aluminum veneer punching, unlimited creativity, new space proposition!

- Punched aluminum veneer, the fashionable choice for modern architecture!

Frequently asked questions

- What are the applications of aluminum veneer in architectural decoration?

- What are the product characteristics of aluminum veneer?

- What is the environmental performance of aluminum veneer?

- What safety issues should be paid attention to in the production and manufacturing of aluminum veneer?

- How to improve the product quality and performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Detailed explanation of the manufacturing process and process flow of aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: February 25, 2025 06:31:57

- Click:0

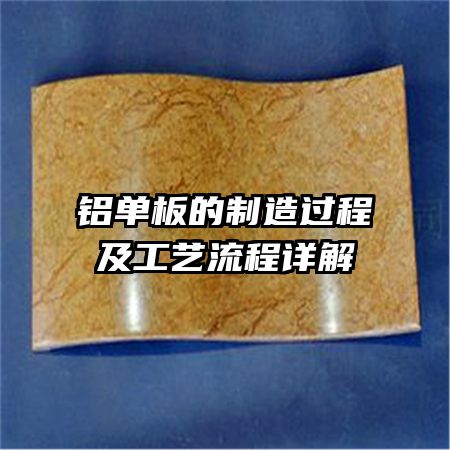

Detailed explanation of the manufacturing process and process flow of aluminum veneer

Abstract: As a commonly used building decoration material, the manufacturing process and technological process of aluminum veneer are crucial for product quality. This article will provide a detailed explanation of the manufacturing process and process flow of aluminum veneer from four aspects.

1、 Raw material preparation

1. Choose aluminum material: High purity aluminum material is used as the raw material for aluminum veneer, usually aluminum alloy, which has good weather resistance and corrosion resistance.

2. Aluminum pre-treatment: Firstly, the aluminum material is cut, planed, and processed to ensure that its size and surface flatness meet the requirements.

3. Surface treatment: By chemical treatment or electrochemical treatment, the adhesion of aluminum surface is improved, and its corrosion resistance and weather resistance are increased.

2、 Aluminum veneer production

1. Aluminum veneer shearing: According to the requirements of the design drawings, the pre treated aluminum material is sheared into appropriate sizes, usually using a shearing machine.

2. Surface treatment: Surface treatment of cut aluminum veneer, such as painting, spraying, etc., to increase its decorative and protective effects.

3. Forming processing: The processed aluminum veneer is formed and processed, usually using a press machine, and subjected to bending, embossing, and other treatments as needed.

3、 Process control

1. Good production plan: Develop a reasonable production plan to ensure coordination between raw material supply and production schedule, prevent material waste and production delays.

2. Quality inspection: Strict quality inspections are conducted at every production stage, including raw material inspection, processing inspection, and final product inspection, to ensure that product quality meets standards.

3. Process improvement: Continuously summarize experience, improve process flow, enhance production efficiency and product quality, and reduce production costs.

4、 Quality Control and Testing

1. Appearance inspection: Inspect the appearance of aluminum veneer, including color, glossiness, flatness and other indicators, to ensure that the product meets the design requirements.

2. Mechanical performance testing: Evaluate the mechanical properties of aluminum veneer, such as strength and stiffness, through testing methods such as tensile testing and bending testing.

3. Weather resistance test: Expose aluminum veneer samples to natural environments to observe their weather resistance performance, in order to verify the product's service life in outdoor environments.

5、 Summary:

The manufacturing process and technological flow of aluminum veneer have a significant impact on product quality and performance. Reasonable arrangements and strict implementation of raw material preparation, aluminum veneer production, process control, quality control and testing can ensure the high quality and stable performance of aluminum veneer manufacturing. In the future, with the continuous development of technology, the manufacturing process of aluminum veneer will also continue to innovate and improve, providing higher quality products for building decoration.

Customer service QQ

Customer service QQ