Industry information

Company News

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- The charm of aluminum veneer: the perfect combination of lightness and sturdiness

- Fluorocarbon aluminum veneer: the "fashionable coat" of modern architecture

- Carved aluminum veneer: a magnificent turn of aluminum art

Industry dynamics

- Carved aluminum veneer: a fashionable element in modern architecture

- Aluminum veneer has low cost

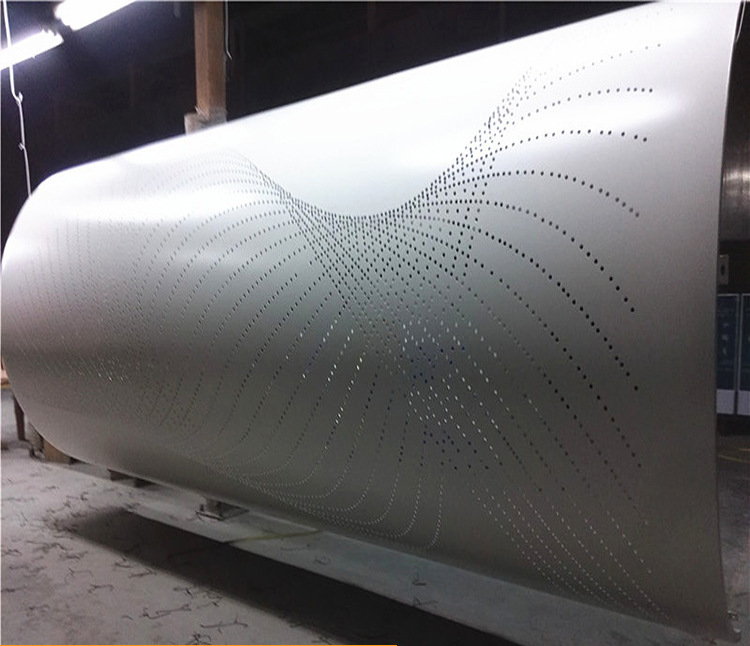

- New trend of aluminum veneer: punching creativity, master of space transformation

- Is the innovative trend of aluminum veneer in architectural exterior design worth paying attention to?

- Fluorocarbon aluminum veneer: the fashionable choice for modern architecture?

Frequently asked questions

- What is the processing and manufacturing process of aluminum veneer?

- What factors affect the production and sales of aluminum veneer?

- What is the future market development trend of aluminum veneer?

- What safety issues should be paid attention to in the production and manufacturing of aluminum veneer?

- What are the product characteristics of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

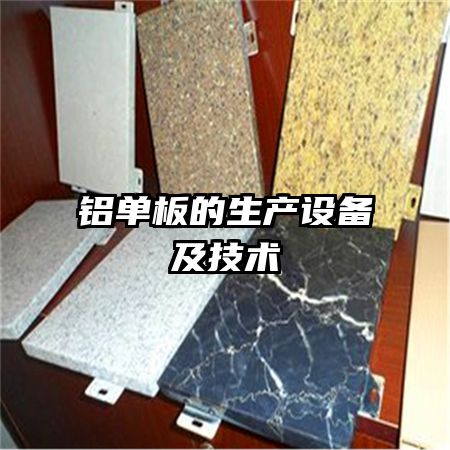

Production equipment and technology for aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: February 25, 2025 00:55:00

- Click:0

Production equipment and technology for aluminum veneer

Abstract: Aluminum veneer is a lightweight metal material widely used in the field of architectural decoration, and its production requires various equipment and technologies. This article will provide a detailed explanation of the production equipment and technology for aluminum veneer from the following four aspects.

1、 Raw material preparation

1. Material selection: The main raw material for aluminum veneer is high-purity aluminum alloy sheet. Choosing aluminum alloy with stable quality and moderate hardness can ensure the quality and performance of the product.

2. Pre treatment of Aluminum Alloy Plates: Prior to production, aluminum alloy plates need to be cleaned, degreased, and polished to ensure surface smoothness and adhesion, in preparation for subsequent coating and processing.

3. Coating selection: Depending on different requirements and environmental conditions, using different types of coatings can enhance the corrosion resistance, weather resistance, and aesthetics of aluminum veneer.

2、 Processing and Forming

1. Cutting and punching: Using mechanical cutting and punching equipment, aluminum alloy sheets are cut and processed according to design requirements to form the required size and shape.

2. Bending and Forming: Using bending equipment, aluminum alloy sheets are bent and formed to produce various aesthetically pleasing aluminum veneers.

3. Surface treatment: By spraying, drawing and other processes, the surface of aluminum veneer is treated with color and texture to increase its decorative effect and durability.

3、 Connection and installation

1. Installation system design: Based on the specific building structure and requirements, design a suitable installation system, including support structures, connectors, sealing materials, etc., for fixing and connecting aluminum veneers.

2. Connection technology: Different connection methods such as bolts, welding, and bonding are used to ensure the firmness and stability between the aluminum veneer and the building.

3. Installation method: According to the design plan and construction requirements, select the appropriate installation method and install the aluminum veneer in the specified position and sequence to ensure the overall effect and quality.

4、 Quality Control and Inspection

1. Raw material inspection: Conduct chemical composition, mechanical properties, and surface treatment tests on incoming aluminum alloy sheets to ensure they meet product requirements.

2. Process control: Strictly control the process parameters and quality standards of cutting, bending, surface treatment and other processing steps to ensure good processing results.

3. Finished product inspection: Testing the appearance quality, dimensional accuracy, coating adhesion, and other aspects of finished aluminum veneer to ensure that the product meets customer requirements and relevant standards.

5、 Summary:

The production equipment and technology of aluminum veneer are important links to ensure product quality and effectiveness. By selecting raw materials reasonably, scientific processing and forming, reliable connection and installation, and strict quality control and inspection, aluminum veneer products with excellent performance and aesthetic effects can be produced. With the development of the construction industry, the application prospects of aluminum veneer will be even broader.

Customer service QQ

Customer service QQ