Industry information

Company News

- How much do you know about aluminum veneer: an elegant choice for modern architecture?

- Aluminum veneer customization, creating personalized spatial aesthetics

- The current situation and development trend of the aluminum veneer market

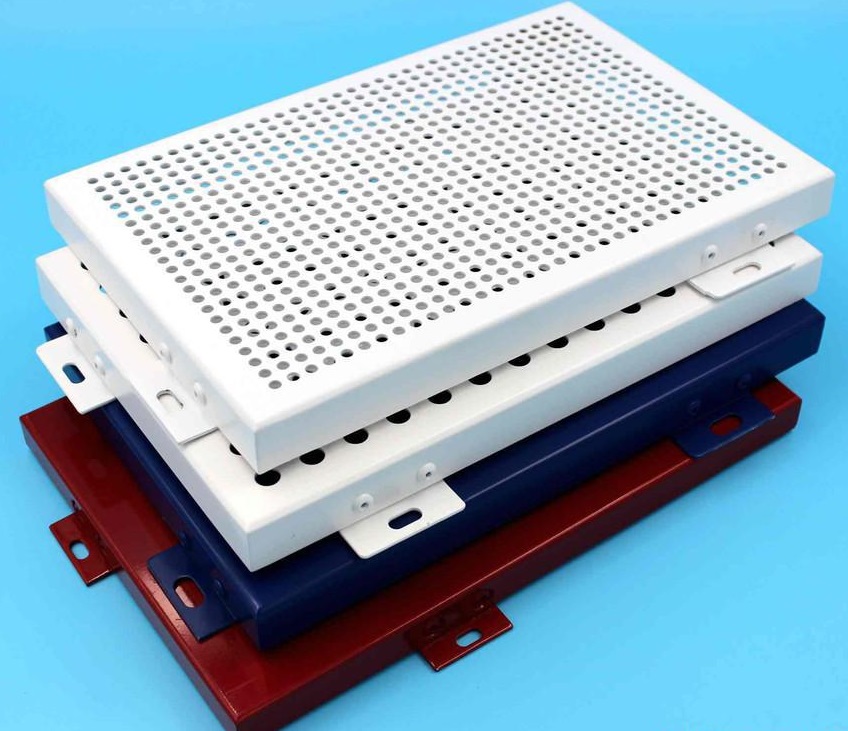

- Innovators in the World of Aluminum Plates: Unveiling the Beauty of Punched Aluminum Veneers

- Curtain wall aluminum veneer: the fashionable coat of architecture, revealing the secrets behind it

Industry dynamics

- Aluminum veneer: not just sheet metal, but also a fashionable business card for architecture

- The charm of aluminum veneer: it's not just about its appearance!

- Can the decorative effect of aluminum veneer be customized?

- Fashion carved hyperbolic aluminum veneer application

- Design and Installation of Outdoor Aluminum Curtain Wall

Frequently asked questions

- What safety issues should be paid attention to in the production and manufacturing of aluminum veneer?

- What are the applications of aluminum veneer in architectural decoration?

- What conditions are required for the production of aluminum veneer?

- What is the environmental performance of aluminum veneer?

- What factors affect the production and sales of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to improve the insulation performance of aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- 发布时间:2025-03-18 03:38:18

- Click:0

Aluminum veneer, as a common building material, its insulation performance is one of the important factors affecting its service life and comfort. In order to improve the insulation performance of aluminum veneer, it is necessary to start from multiple aspects, such as material selection, structural design, etc. Below, we will provide a detailed introduction on how to improve the insulation performance of aluminum veneer.

1、 Optimize material selection

When improving the insulation performance of aluminum veneer, the first step is to optimize material selection. High quality insulation materials have high insulation and corrosion resistance, which can improve the insulation performance of aluminum veneer. Attention should also be paid to the thickness and shape design of materials to increase the stability and load-bearing capacity of aluminum veneer.

2、 Optimize structural design

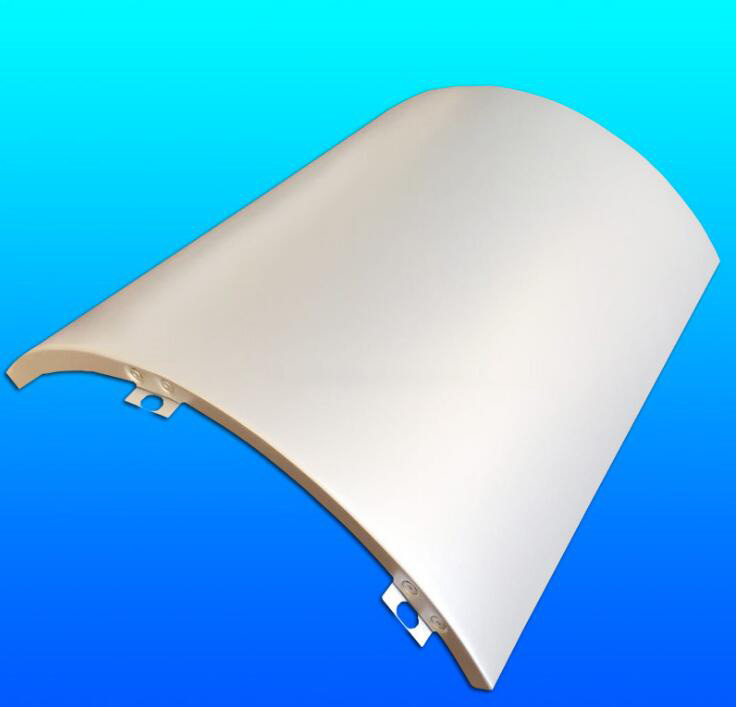

When improving the insulation performance of aluminum veneer, it is also necessary to optimize the structural design. The stability and load-bearing capacity of aluminum veneer can be increased through reasonable construction and support systems. Attention should also be paid to the connection and fixing methods of the structure to ensure its reliability and safety. A double-layer or three-layer structure design can also be used to increase the insulation performance of aluminum veneer.

3、 Strengthen surface treatment

When improving the insulation performance of aluminum veneer, it is also necessary to strengthen surface treatment. Different surface treatment methods, such as spraying and roll forming, can be used to enhance the aesthetic and decorative appeal of aluminum veneer. Attention should also be paid to the flatness and smoothness of the surface to reduce air resistance and friction, and improve the insulation performance of aluminum veneer.

4、 Strengthen the design of the insulation layer

When improving the insulation performance of aluminum veneer, it is also necessary to strengthen the design of the insulation layer. It is possible to reduce heat transfer and cooling loss by increasing the thickness and density of the insulation layer. Attention should also be paid to the material and construction process of the insulation layer to ensure its reliability and effectiveness.

5、 Strengthen quality control

When improving the insulation performance of aluminum veneer, it is also necessary to strengthen quality control. By establishing a comprehensive quality management system and strengthening the quality inspection and monitoring of raw materials, production processes, and finished products, the stability and reliability of aluminum veneer quality can be ensured. We should also pay attention to the standardization and normalization of product design and manufacturing processes to improve product consistency and comparability.

Improving the insulation performance of aluminum veneer requires starting from multiple aspects, including optimizing material selection, optimizing structural design, strengthening surface treatment, enhancing insulation layer design, and strengthening quality control. Only by comprehensively strengthening these aspects of work can we truly achieve the improvement of insulation performance and sustainable development of aluminum veneer.

Customer service QQ

Customer service QQ