Industry information

Company News

- The Charm of Holes: Unveiling the Charm and Practicality of Punched Aluminum Veneers

- Aluminum veneer: the beauty of light luxury, the new favorite of home furnishings

- Fluorocarbon aluminum veneer: a modern interpretation of architectural aesthetics

- Aluminum veneer curtain wall, a new chapter in architectural aesthetics

- Aluminum veneer, the new darling of architectural aesthetics!

Industry dynamics

- 2. Customize aluminum veneer to give your home a brand new look Aluminum veneer customization, personalized decoration

- Punched aluminum veneer: the new darling of architectural art

- Space saving punched aluminum veneer

- Aluminum veneer customization, creating the art of personalized space

- Fluorocarbon aluminum veneer: the 'invisible hero' of the construction industry?

Frequently asked questions

- What are the applications of aluminum veneer in architectural decoration?

- What is the future market development trend of aluminum veneer?

- What is the sales market for aluminum veneer?

- What factors affect the production and sales of aluminum veneer?

- What safety issues should be paid attention to in the production and manufacturing of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to control the production cost of aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: February 26, 2025 18:42:01

- Click:0

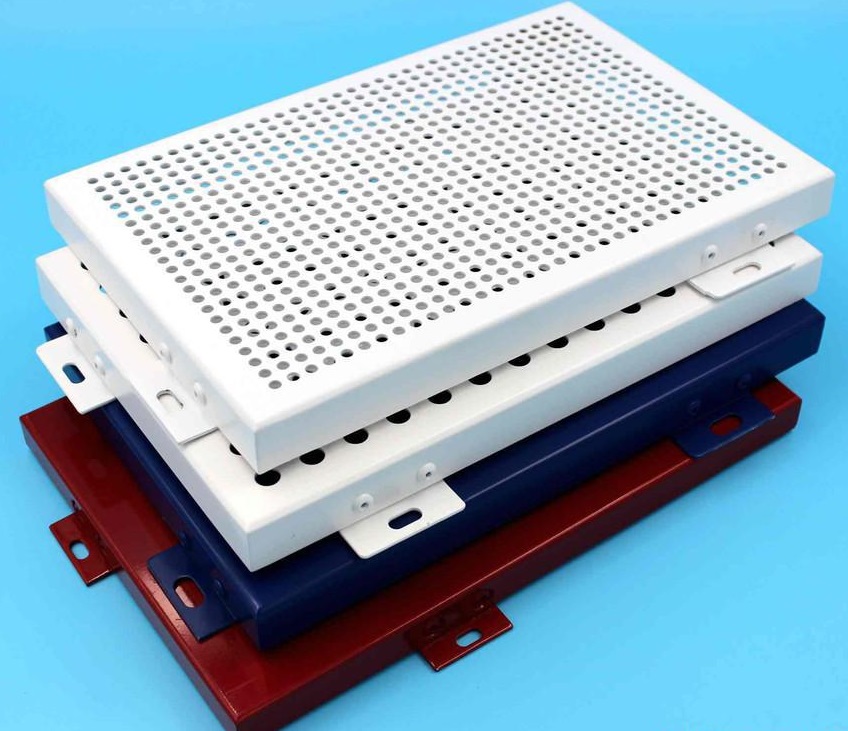

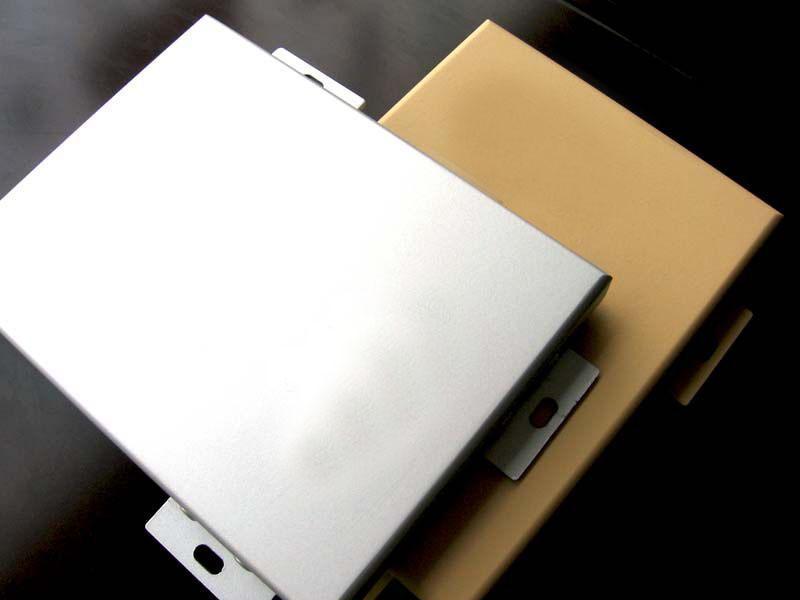

As a new type of building material, controlling the production cost of aluminum veneer is crucial for enterprises. Below, we will introduce some methods for controlling production costs of aluminum veneer.

1. Optimize production processes and equipment

Optimizing production processes and equipment is one of the important means to reduce production costs. By introducing advanced production processes and technological equipment, production efficiency and product quality can be improved, while also reducing energy consumption and raw material usage, thereby lowering production costs. Existing production processes and equipment can also be improved and upgraded to further enhance production efficiency and reduce costs.

1. Reasonably plan the procurement of raw materials

Reasonable planning of raw material procurement is also one of the important means to reduce production costs. Enterprises should develop a reasonable raw material procurement plan based on actual demand and market prices to avoid excessive or insufficient procurement. By establishing long-term cooperative relationships with suppliers, we can strive for more favorable prices and better services, thereby reducing procurement costs.

1. Strengthen personnel training and management

Strengthening personnel training and management is also one of the important means to reduce production costs. By training employees to master advanced production processes and technologies, production efficiency and product quality can be improved, while also reducing waste and losses caused by improper or erroneous operations. By managing employees, we can improve their quality and work efficiency, thereby reducing production costs.

1. Optimize supply chain management

Optimizing supply chain management is also one of the important means to reduce production costs. Enterprises should establish long-term cooperative relationships with suppliers to jointly optimize supply chain management and reduce logistics and inventory costs. Advanced information technology can also be used to achieve digital management and intelligent operation of the supply chain, further improving the efficiency and effectiveness of supply chain management.

Aluminum veneer production enterprises need to take various measures to control production costs. In addition to the methods mentioned above, one can also choose appropriate methods for implementation based on their own situation. Only by continuously optimizing production processes, equipment, raw material procurement, personnel training and management, supply chain management, and other aspects, can production costs be effectively controlled, and the competitiveness and profitability of enterprises be improved.

Customer service QQ

Customer service QQ