Industry information

Company News

- Aluminum veneer: a modern interpretation of industrial aesthetics

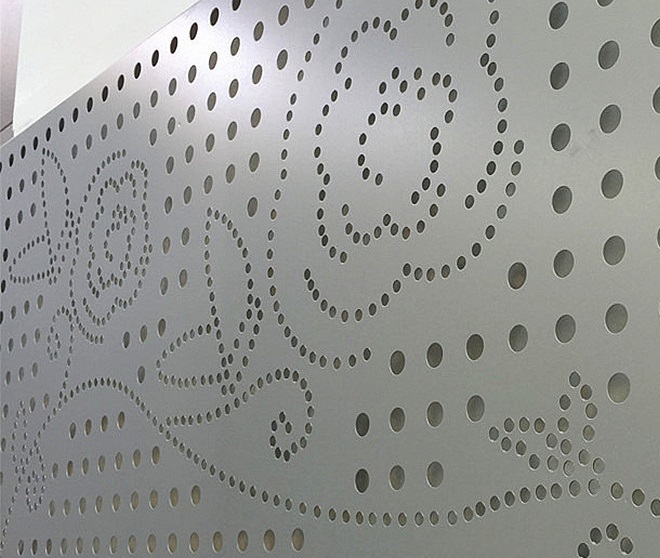

- Customized aluminum veneer, a new choice for personalized space

- The Charm of Aluminum Veneer: A Light Luxury Choice with Unlimited Creativity

- Aluminum veneer customization, creating a new trend of personalized space

- The performance of aluminum veneer in insulation and heat preservation

Industry dynamics

- What is the frost resistance of fluorocarbon aluminum veneer?

- Maintenance and upkeep guide for customized aluminum veneer

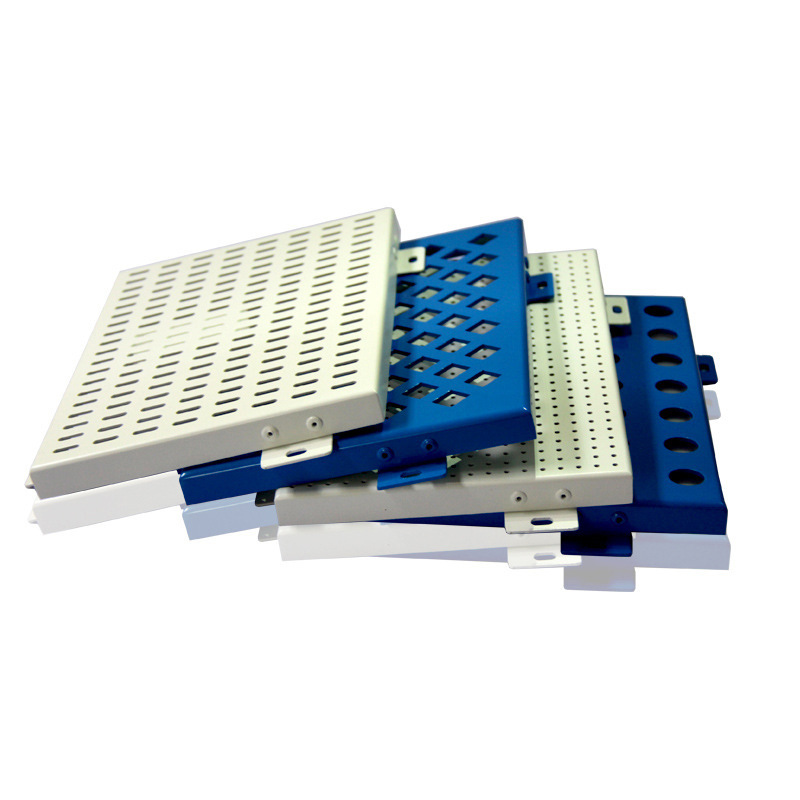

- Aluminum veneer punching, unlimited creativity, new space proposition!

- Aluminum veneer: The secret story behind its lightweight design

- Innovative design of wood grain aluminum veneer curtain wall makes stunning debut

Frequently asked questions

- What are the applications of aluminum veneer in architectural decoration?

- What safety issues should be paid attention to in the production and manufacturing of aluminum veneer?

- What are the product characteristics of aluminum veneer?

- What is the future market development trend of aluminum veneer?

- What is the environmental performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to choose high-quality fluorocarbon aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- 发布时间:2025-03-19 06:16:53

- Click:0

Fluorocarbon aluminum veneer is a very popular building material, and its quality directly affects the service life and aesthetics of buildings. How to choose high-quality fluorocarbon aluminum veneer is very important. Below is a detailed introduction on how to choose high-quality fluorocarbon aluminum veneer.

1、 Manufacturer reputation

The first step in choosing high-quality fluorocarbon aluminum veneer is to choose a reputable manufacturer. You can learn about the manufacturer's production scale, production process, product quality, and other aspects through online search and consulting with industry professionals. Choosing a reputable manufacturer can ensure that the purchased fluorocarbon aluminum veneer has good quality and after-sales service.

2、 Product specifications

When selecting fluorocarbon aluminum veneer, it is necessary to choose the appropriate product specifications according to actual needs. Generally speaking, the larger the specification of fluorocarbon aluminum veneer, the higher its price, but its strength and stiffness also increase accordingly. When selecting product specifications, it is necessary to comprehensively consider factors such as the structural requirements and economic viability of the building.

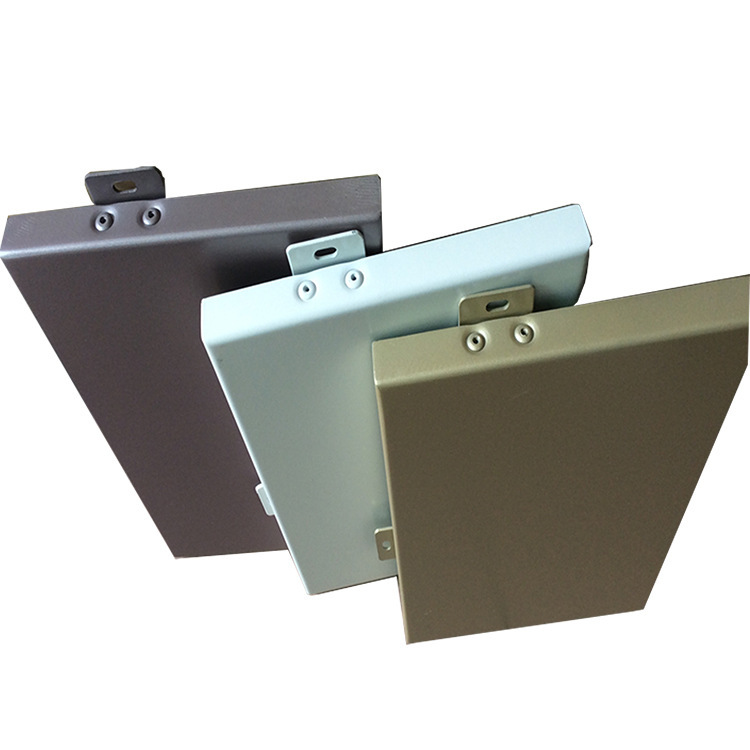

3、 Surface treatment

The surface treatment of fluorocarbon aluminum veneer has a significant impact on its durability and aesthetics. When choosing fluorocarbon aluminum veneer, attention should be paid to the quality of surface treatment. Generally speaking, surface treatment should be uniform, smooth, free of bubbles and cracks, and should have good weather resistance and corrosion resistance.

4、 Thickness and strength

The thickness and strength of fluorocarbon aluminum veneer are also important factors in choosing high-quality products. Generally speaking, thicker fluorocarbon aluminum veneers have better strength and stiffness, and can withstand greater loads. However, excessive fluorocarbon aluminum veneer can affect the overall weight and appearance of the building. When selecting product thickness, it is necessary to comprehensively consider the relationship between these factors.

5、 Quality Inspection Report

When purchasing fluorocarbon aluminum veneer, the manufacturer can be requested to provide a quality inspection report. By checking the quality inspection report, we can understand the performance indicators, chemical composition, and other aspects of the product, in order to determine whether the quality of the product meets the requirements.

Choosing high-quality fluorocarbon aluminum veneer requires comprehensive consideration of multiple factors such as manufacturer reputation, product specifications, surface treatment, thickness and strength, and quality inspection reports. Only by comprehensively considering these factors can high-quality fluorocarbon aluminum veneer products that meet actual needs be selected.

Customer service QQ

Customer service QQ